Fertilization with Buffer Tank in Cocopeat and Hydroponic Systems: Professional Guide

The biggest challenge faced by producers engaged in cocopeat and hydroponic cultivation is the precise management of the nutrient solution. Sudden EC and pH fluctuations in traditional fertilizer injection systems can lead to damages worth thousands of liras. But what if fertilizers were mixed and optimized in a controlled environment before being delivered to the main line? This is exactly what buffer tank technology does.

In this guide, you will learn how the buffer tank system works in professional cocopeat and hydroponic production, why it is necessary, and how the Esular Smart Agro MEGA solution provides a yield increase.

Cocopeat and Hydroponics: Environments with Zero Error Tolerance

Unlike soil-based agriculture, cocopeat and hydroponic systems do not have buffering capacity. This situation makes nutrient management extremely critical.

Soil vs. Cocopeat: Critical Differences

Cultivation in Soil: Soil has the ability to hold nutrients within itself and absorb sudden changes. Even if the pH varies between 5.5-7.5, plants can adapt to this situation. Even changes of ±0.5 mS/cm in EC values are buffered by the soil.

Cocopeat and Hydroponic Systems: Although cocopeat, obtained from coconut fibers, has excellent aeration and water retention properties, it has no buffering capacity. Even the smallest changes in the nutrient solution reach the plant roots directly.

| Feature | Soil | Cocopeat/Hydroponic |

|---|---|---|

| Buffering Capacity | High | None ❌ |

| EC Tolerance | ±0.5 mS/cm | ±0.2 mS/cm |

| pH Flexibility | 5.5-7.5 | 5.5-6.5 |

| Nutrient Homogeneity | Insignificant | CRITICAL ⚠️ |

| Sudden Change Effect | Slow | SUDDEN and DESTRUCTIVE 🔥 |

Importance of EC and pH Sensitivity

EC (Electrical Conductivity): It is the value showing the total salt concentration in the nutrient solution. In cocopeat cultivation, ideal EC values vary depending on the product but are generally between 1.5-2.5 mS/cm. Research shows that even a sudden EC increase of 0.3 mS/cm can lead to plant stress.

pH Value: Directly affects the availability of nutrients to be taken up by plants. In hydroponic and cocopeat systems, the ideal pH range is 5.8-6.2. When going outside this range, the uptake of iron, phosphorus, and other micro-elements decreases significantly.

Limitations of Traditional Fertilization Systems

As cocopeat and hydroponic cultivation became more widespread, the inadequacies of traditional fertilization systems also began to emerge.

Venturi/Dozatron Type Injectors

Working Principle: Performs mechanical dosing with pressure difference. Does not require electricity and is easy to install.

Basic Problem: No EC/pH control. Fertilizer concentration varies depending on pressure. Homogeneity guarantee cannot be provided.

Suitable Use: Open field agriculture, soil-based production, garden irrigation.

❌ For Cocopeat/Hydroponics: NOT SUITABLE

Standard Injection Systems (EC/pH Controlled)

Working Principle: Fertilizers drawn from different fertilizer tanks with proportional pumps are injected into the main line. EC and pH sensors are available.

Critical Limitation: Measurement is made when fertilizers mix in the main line, but there is no buffering system to prevent sudden changes. Even a small flow change in the system can affect the concentration.

Suitable Use: Medium sensitivity applications, soil-based greenhouse vegetable growing.

⚠️ For Cocopeat/Hydroponics: Usable but NOT OPTIMAL

"But what if fertilizers were mixed in a controlled environment BEFORE being delivered to the main line, and sent to plants AFTER pH/EC was optimized? This is exactly what Buffer Tank technology does..."

Buffer Tank Technology: A Revolutionary Solution

💡 WHAT IS A BUFFER TANK?

"Buffer" means "tampon" in Turkish. A buffer tank is an intermediate storage tank where the fertilizer mixture is prepared, homogenized, and optimized BEFORE being delivered to the main irrigation line. The pH and EC values of the nutrient solution are brought to the ideal level here before being sent to the plants.

Buffer Tank System: Step-by-Step Operation

STEP 1 – Fertilizer Drawing: The programmed recipe comes into play. Fertilizers are drawn from four tanks in specific ratios (e.g., Tank A: 2.5L, Tank B: 1.8L, Tank C: 0.4L, Tank D: 0.3L).

STEP 2 – Transfer to Buffer Tank: Drawn fertilizers and clean water are taken into the 50-200L capacity buffer tank.

STEP 3 – Magnetic Mixing: The magnetic motor runs for 2-5 minutes to create a 100% homogeneous mixture. Even micro-elements are distributed evenly.

STEP 4 – Measurement and Optimization: EC and pH sensors inside the buffer tank perform continuous measurements. Target values:

- Target EC: 2.0 mS/cm → Current: 2.15 mS/cm → System performs automatic dilution ✅

- Target pH: 6.0 → Current: 6.4 → Acid dosing is performed ✅

STEP 5 – Controlled Output: READY and OPTIMIZED nutrient solution exits from the buffer tank. Balanced feeding is provided to plants, the risk of sudden shock is ZERO.

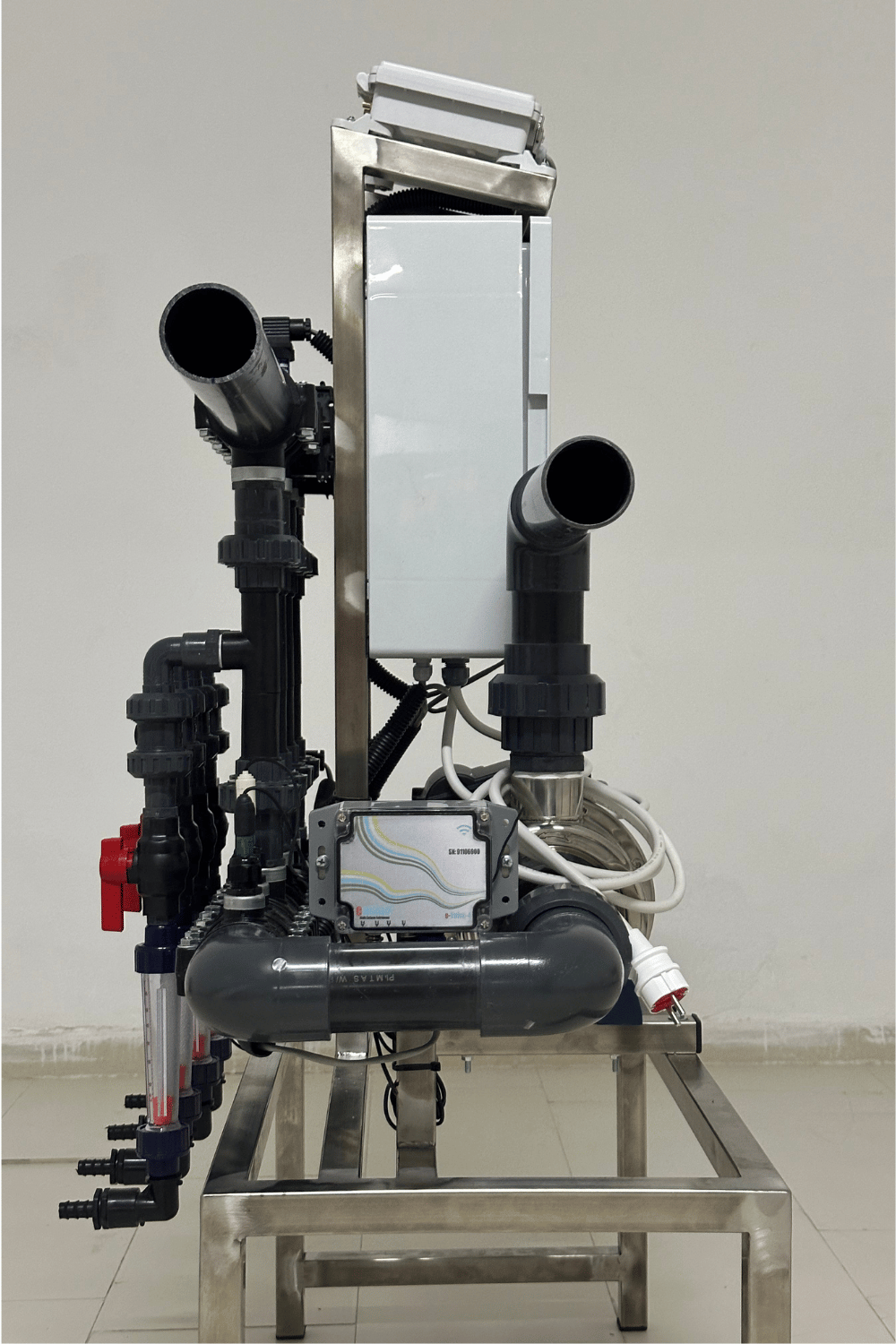

Smart Agro MEGA: Turkey's First Fertilization System with Buffer Tank

Esular developed Smart Agro MEGA as a result of years of R&D studies. MEGA is the first professional fertilization system with buffer tank + magnetic mixing features produced in Turkey and is specifically designed for professional cocopeat/hydroponic producers.

⚠️ IMPORTANT INFORMATION: Buffer tank and magnetic mixing technology are only available in the MEGA model. Smart Agro MINI and MAXI models are venturi (pressure difference) type systems and are not recommended for cocopeat/hydroponic cultivation. These models are suitable for soil-based greenhouse and field applications.

Unique Features of Smart Agro MEGA

- ✅ Buffer Tank Technology: Fertilizers are mixed and optimized in a special tank before being delivered to the main line

- ✅ Magnetic Mixing Motor: 100% silent, maintenance-free, long-lasting mixing system

- ✅ 6 Fertilizer Tanks: Managing different fertilizer formulations at the same time

- ✅ Precise EC/pH Control: Measurement and automatic adjustment with ±0.05 mS/cm sensitivity

- ✅ Wireless Communication: Remote monitoring with WiFi + GSM + LoRa technology

- ✅ 6000L/Hour Capacity: Sufficient for large-scale production facilities

- ✅ Mobile Application: Full control via iOS, Android, and Web

Magnetic Mixing System: Technological Superiority

Traditional Mixers:

- ❌ Mechanical impeller (inside the tank)

- ❌ Friction and wear

- ❌ High risk of clogging

- ❌ Requires regular maintenance

- ❌ Noisy operation

Magnetic Mixing (in MEGA):

- ✅ Magnetic motor OUTSIDE the tank

- ✅ Impeller INSIDE the tank

- ✅ NO mechanical contact between them

- ✅ Rotation via magnetic field

Advantages:

- ✅ ZERO risk of clogging

- ✅ 100% silent operation

- ✅ Minimum maintenance (10+ years lifespan)

- ✅ Guarantee of full homogeneous mixture

- ✅ Energy saving (40% less consumption)

Comparison of Smart Agro Models

| Feature | Smart Agro MINI | Smart Agro MAXI | Smart Agro MEGA ⭐ |

|---|---|---|---|

| System Type | Venturi | Venturi | Buffer Tank |

| Control Type | Manual | Automatic | Fully Automatic + Buffer |

| Fertilizer Tank | 4 units | 4 units | 6 units |

| Magnetic Mixing | ❌ | ❌ | ✅ ⭐ |

| EC/pH Control | Basic | Advanced | Professional |

| Wireless Communication | WiFi | WiFi + GSM | WiFi + GSM + LoRa |

| EC Fluctuation | ±0.5 mS/cm | ±0.3 mS/cm | ±0.05 mS/cm ⭐ |

| Homogeneity Guarantee | Basic | Good | Excellent ⭐ |

| Cocopeat Suitability | ❌ Not recommended | ❌ Not recommended | ✅ PROFESSIONAL ⭐ |

| Hydroponic Suitability | ❌ Not recommended | ❌ Not recommended | ✅ PROFESSIONAL ⭐ |

| Suitable Usage Area | Small soil-based production | Medium-scale soil-based greenhouse | Professional cocopeat/hydroponic |

| ROI Period | 24-30 months | 18-24 months | 12-18 months ⭐ |

💡 WHY MEGA?

The key to success in cocopeat and hydroponic systems is a homogeneous and stable nutrient solution. Venturi systems (Mini/Maxi) operate with pressure difference and do not allow precise control. The buffer tank technology in MEGA ensures that fertilizers are brought to optimum values before being delivered to the main line. 100% homogeneous distribution is achieved with magnetic mixing. This is vital in cocopeat and hydroponics.

7 Tangible Benefits with Smart Agro MEGA

1. Plant Shock Risk: 100% Reduction

Thanks to precise EC and pH control, sudden changes are completely prevented. EC fluctuation, which is ±0.3-0.5 mS/cm in traditional systems, drops to ±0.05 mS/cm with Smart Agro MEGA. Result: Stress-free plants, higher quality, and yield.

2. Fertilizer Saving: In the Range of 15-25%

Thanks to homogeneous nutrient distribution, each plant receives exactly as much nutrient as it needs. There is no waste. Fertilizer savings are provided at the sector average. In large enterprises, this means savings of tens of thousands of liras annually.

3. Yield Increase: 30-40%

Optimal and balanced nutrition ensures maximum growth.

4. Product Quality: Standardization

When all plants receive equal nutrients, product size, color, and taste become standardized. The ratio of A+ class products for export increases. You can produce at the homogeneous quality demanded by markets.

5. Labor Reduction: 60%

Thanks to full automation, the need for manual fertilizer mixing, tank cleaning, and continuous control is eliminated. The system works by itself; you just follow it from the mobile application.

6. Water Saving: 20-30%

With the fertigation method, water and fertilizer are given at the same time. Unnecessary irrigation is eliminated. When used together with drip irrigation, up to 30% water saving is achieved compared to traditional methods.

7. Remote Monitoring and Control

You can control your system from anywhere in the world with GSM, WiFi, and LoRa connectivity. You keep the production process under your full control with instant alarms, weekly reports, and trend analyses with the mobile application.

Frequently Asked Questions

Q: How big should the buffer tank be?

A: Buffer tank capacity is determined according to business size and irrigation flow rate. General rule: 50L for 1000-2000m², 100L for 2000-4000m², 150-200L buffer tank for 4000m²+. Esular engineers perform free capacity calculations.

Q: Is the magnetic motor really silent?

A: Yes, 100% silent. Since the magnetic motor is outside the tank and there is no mechanical contact, it makes no noise at all. There is a huge difference compared to traditional mixers.

Q: Which fertilizers can be used? Is it compatible with organic fertilizer?

A: Smart Agro MEGA is compatible with all liquid fertilizer types: Chemical liquid fertilizers ✅, Organic certified liquid fertilizers ✅, Microelement mixtures ✅, Acid/Base solutions ✅. Note: Solid fertilizers cannot be used without being dissolved.

Q: What happens in a power outage?

A: Smart Agro MEGA is equipped with a rechargeable Li-ion battery. In case of a power outage, the system continues to work with the battery, an instant alarm goes to the mobile application, and the current mixture in the buffer tank is used.

Q: Is it possible to upgrade from MAXI to MEGA?

A: Yes! A buffer tank module can be added to your existing Smart Agro MAXI system. This is a much more economical solution than investing from scratch. The Esular technical team provides upgrade services.

Q: Is special infrastructure required for installation?

A: Minimal requirement: 220V electricity, clean water source, 2-3m² area (for buffer tank and fertilizer tanks), existing drip irrigation system. 95% of businesses do not require additional infrastructure.

Q: Is it compatible with my old irrigation system?

A: There is 95% compatibility. Smart Agro MEGA is integrated into your existing drip irrigation systems: Old piping ✅, Existing pumps ✅, Filter systems ✅.

Formula for Cocopeat Success: Buffer Tank + Automation

Summary of what you learned in this guide:

- ✅ Precision is vital in cocopeat/hydroponics

- ✅ Traditional systems (venturi, standard injection) fall short

- ✅ Buffer tank technology is a revolutionary solution

- ✅ Magnetic mixing guarantees 100% homogeneity

- ✅ Smart Agro MEGA is Turkey's first system with a buffer tank

- ✅ ROI: Return on investment in 12-18 months

- ✅ Yield increase: 30-40%

- ✅ Fertilizer saving: 15-25%

"If you are engaged in cocopeat or hydroponic cultivation in 2025 and are still not using a buffer tank, you are giving your competitors a serious advantage. The question is: Who will take the first step? You, or your competitor?"

Start with Smart Agro MEGA!

The Esular technical team performs a preliminary assessment for your business and offers the most suitable solution for you.Examine MEGA. Contact Us

📌 Price Information: The prices stated in this content are the list prices prior to the publication date and are subject to change. For current prices and campaigns, please visit the Esular Store page or contact our technical team.