Pump Control with Frequency Drive in Agriculture: Protect Your Pump, Use Energy Efficiently

Irrigation pumps are one of the most critical pieces of equipment in agricultural production. However, electrical fluctuations encountered during the operation of pumps, excessive energy consumption, and maintenance costs are among the significant problems for producers. This is exactly where frequency drives (inverters) come into play.

In this article, we will discuss in detail how frequency drives are used in agriculture, the benefits they provide, and the smart pump control solutions offered by esular with this technology.

What is a Frequency Drive (Inverter)?

A frequency drive is an electronic device used to control the speed of electric motors. These systems, also known as motor drives, variable frequency drives (VFD), or frequency converters, adjust the motor's speed by converting the fixed-frequency electrical current from the grid into variable frequency.

How Does It Work?

Frequency drives operate in three basic stages:

- Rectification: Converts AC (alternating current) electricity from the grid into DC (direct current)

- Filtering: Stabilizes the DC voltage and cleans voltage fluctuations

- Inverter: Converts DC back to variable frequency AC according to the motor's needs

In this way, the pump motor can operate at full speed or at lower speeds according to the water requirement.

7 Important Benefits of Using Frequency Drives in Agriculture

1. Energy Savings: Decrease Between 30-60%

Pumps operating without a frequency drive always run at full speed. However, water demand in agriculture changes constantly. With a frequency drive, unnecessary energy consumption is prevented by adjusting the pump speed according to need.

Real Benefit: Especially in fan and pump applications, energy savings between 30% and 60% can be achieved.

2. Full Protection Against Electrical Fluctuations

Electrical fluctuations are very common in agricultural areas. Sudden voltage increases or decreases occurring in the grid can cause serious damage to the pump motor.

Protection features of the frequency drive:

- Overvoltage protection

- Undervoltage protection

- Phase loss protection

- Overcurrent protection

- Short circuit protection

- Overheating protection

The drive first filters and cleans the electricity coming from the grid. Thus, the motor is always fed with balanced and clean electricity.

3. Extends the Life of the Pump

During pump startup with traditional methods, the motor draws a sudden current as much as 6-8 times its nominal current. This situation puts great stress on both the motor and mechanical parts.

Frequency drives start the pump softly (soft start) and stop it slowly. In this way:

- Mechanical wear is minimized

- Risk of cavitation decreases

- Water hammer (hydraulic shock) is prevented

- Maintenance needs decrease

4. Automatic Pressure Control

In modern agricultural irrigation systems, it is important to operate at constant pressure. Frequency drives keep the pressure in the system constant by working integrated with a pressure sensor.

When water demand decreases, the pump speed automatically drops; when demand increases, the speed rises. Thus:

- Drip irrigation systems operate at optimal pressure

- Filters are not damaged

- Uniform irrigation is ensured

5. Protection Against Harmonic Pollution

Frequency drives minimize harmonics that may occur in the grid. In this way:

- Other electrical equipment is not affected by harmonics

- Grid quality is preserved

- Additional penalties on the electricity bill are prevented

6. Easy Integration and Automation

Modern frequency drives have communication protocols (Modbus, RS485). In this way:

- They work integrated with PLCs and automation systems

- Remote monitoring and control are possible

- Real-time data tracking can be performed

7. Multi-Pump Management

In systems where there is more than one pump, frequency drives ensure equal wear by activating the pumps in sequence.

Next Generation Solution in Frequency Drive Control with esular

esular offers special solutions to the agricultural sector by combining all the advantages of frequency drives with smart irrigation technology.

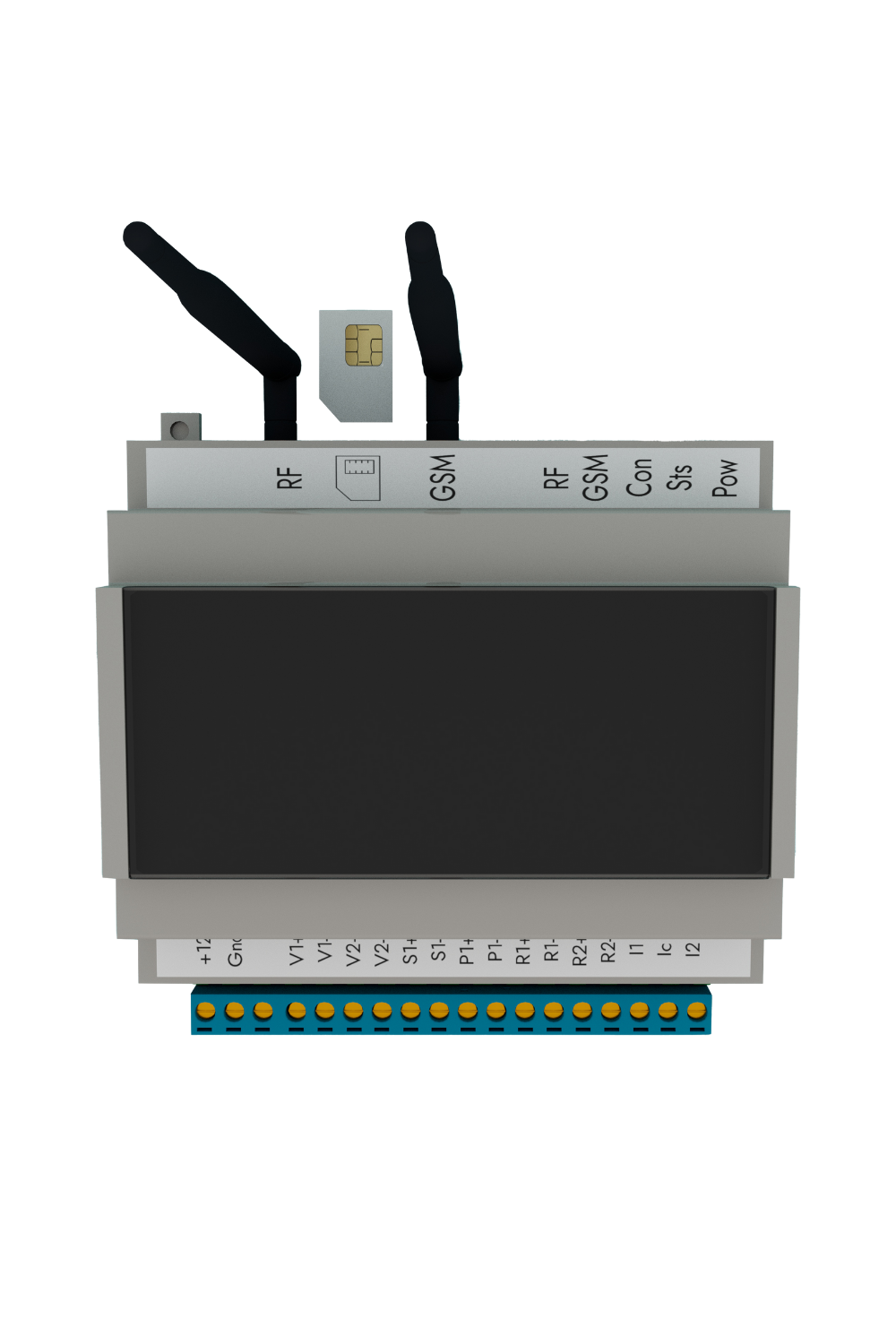

E Series Premium: Energy Analyzer and Inverter Control

esular's E Series Premium Pump Station is the most advanced pump control system used in agriculture.

Highlighted features:

✅ Energy Analyzer Integration: Reads instantaneous data from energy analyzers via Modbus protocol, optimizes energy consumption

✅ Pump Inverter Frequency Control: You can remotely adjust the frequency of the pump inverter (drive)

✅ Automatic Pressure Adjustment: The speed of the pump is automatically adjusted according to the system pressure

✅ Power Outage Notification: You receive an instant notification when the power is cut

✅ Advanced Protection Algorithms:

- Overpressure protection

- Low pressure protection (pipe burst detection)

- Dry run protection

- Overcurrent protection

- Phase loss protection

- Cavitation protection

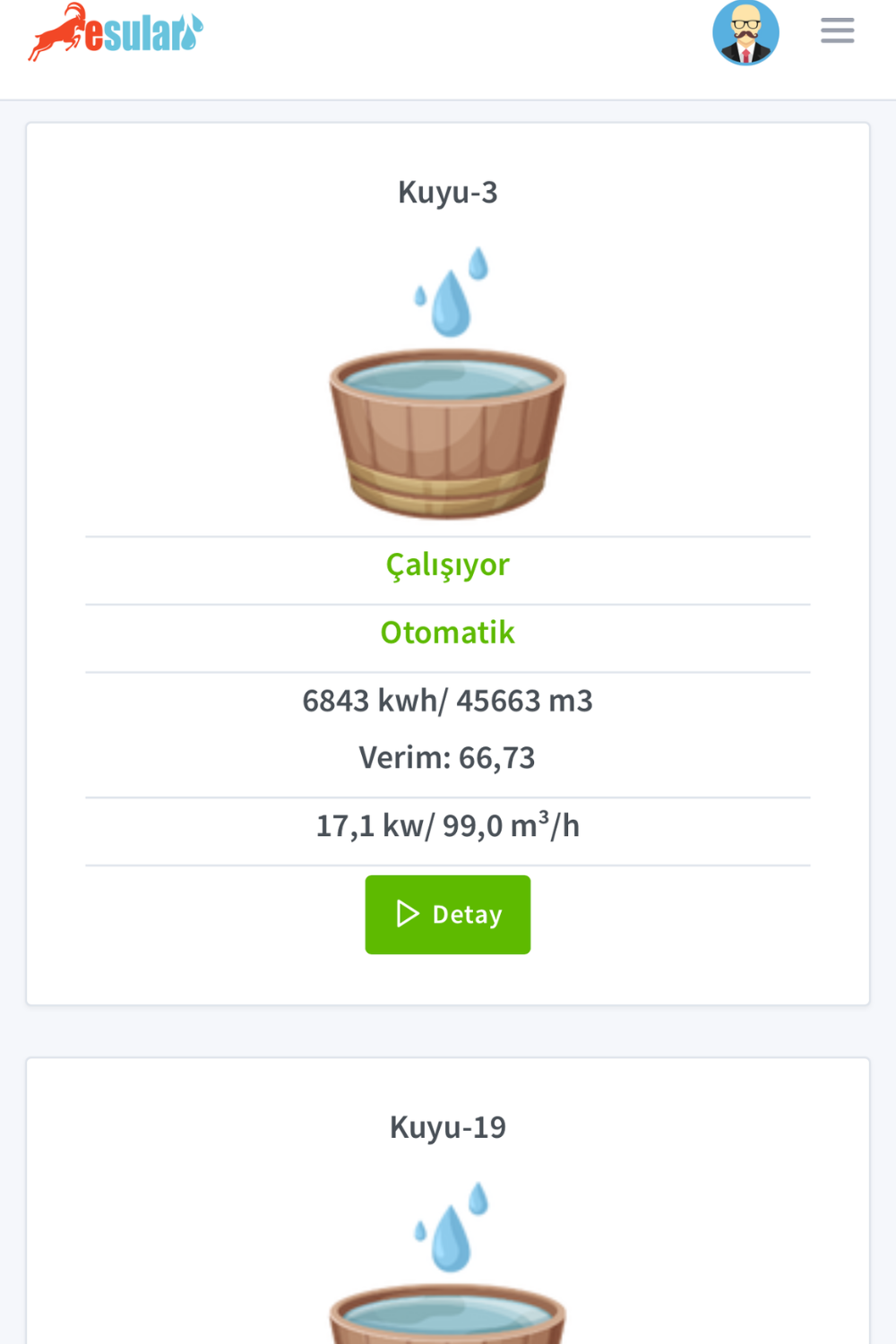

Control from Anywhere in the World

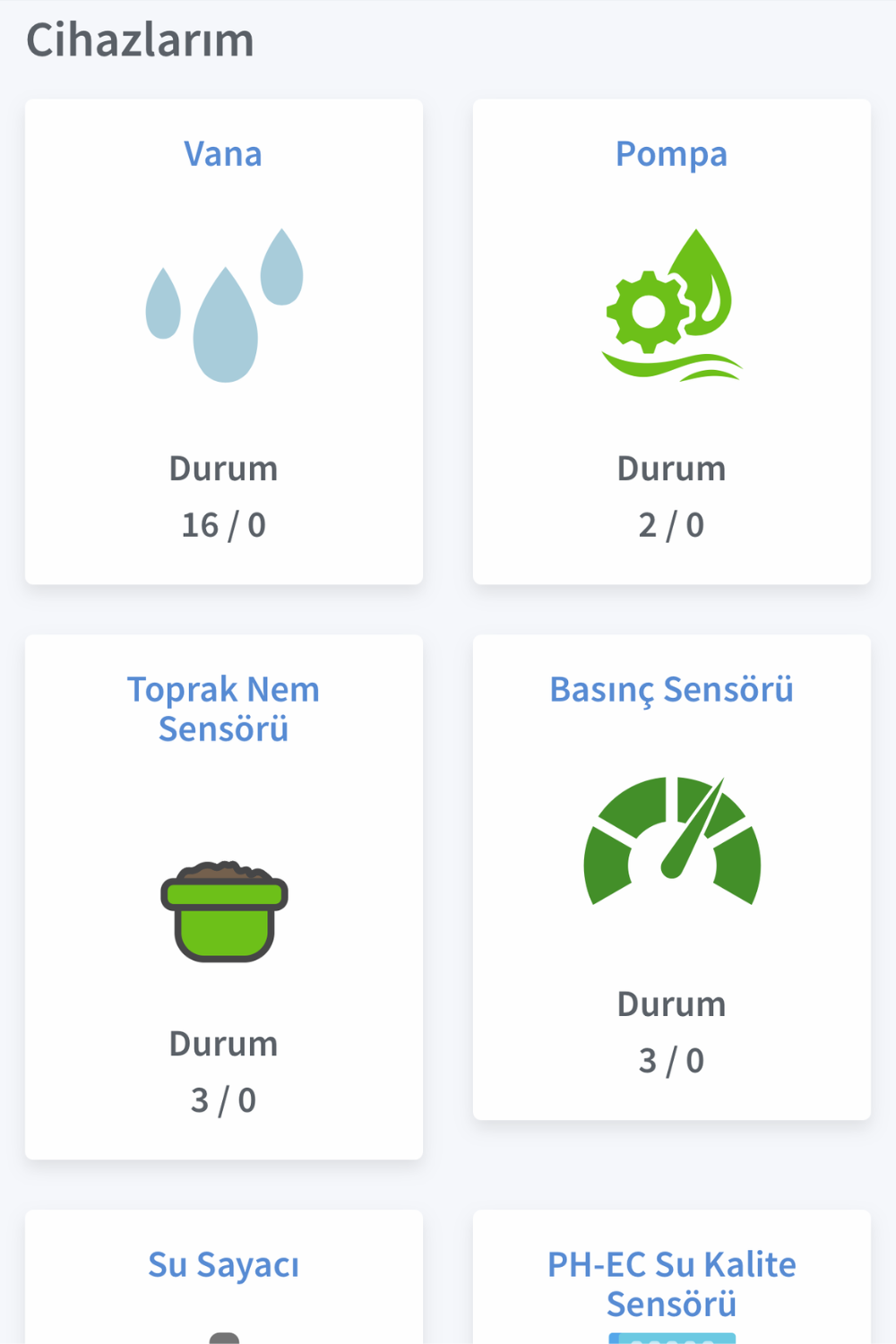

esular systems operate completely wirelessly. It communicates with the cloud server via GSM infrastructure. With the free mobile application on your phone:

- You can turn your pump on and off

- You can change the frequency value instantaneously

- You can monitor energy consumption

- You can see pressure and flow data

- You receive alarms and warnings instantly

Real User Experience

One of our producers producing tomatoes in a 50-decare greenhouse in Antalya, after integrating the frequency drive with esular E Series Premium:

- Achieved a reduction in the monthly electricity bill

- Pump failure was completely eliminated

- Increased irrigation quality by making pressure adjustments via phone

- Was instantly informed of power outages

Smart Control at a More Affordable Price with F Series

If you are looking for a budget-friendly solution, the F Series is just for you.

With the F Series, you can turn your pump on and off remotely, monitor its operating status, and benefit from basic protection features.

With the Mid-Segment package, pressure sensors and automatic protection systems can also be added.

Things to Consider When Choosing a Frequency Drive

- Suitability for Motor Power: The power of the drive should be equal to or slightly higher than the power of the pump motor

- Input Voltage: A model suitable for your single-phase (220V) or three-phase (380V) grid structure should be selected

- Environmental Conditions: An appropriate IP protection class against dust, humidity, and temperature should be selected

- Communication Protocol: If there is protocol support such as Modbus or RS485, it can be integrated into your automation system

- Brand and Service: Selection of a quality brand and local service support is important

Conclusion: Investing in the Future with Smart Pump Control

Digitalization in agriculture is inevitable. Smart pump control with frequency drives:

✅ Reduces energy costs by 30-60%

✅ Extends equipment life

✅ Protects against electrical fluctuations

✅ Provides labor savings

✅ Increases irrigation quality

With esular, you can manage this technology via mobile application, analyze your data, and continuously optimize your system.

Discover esular Pump Control Systems

Are You Ready to Make Your Pump Smart?

Our expert team is ready to offer you the most suitable solution. Contact us now for a free discovery and offer.Examine F Series Examine E Series Premium

Related Products

- F Series Basic Pump Station

- F Series Mid-Segment Pump Station

- E Series Premium Pump Station

- Wireless Pressure Sensor

Frequently Asked Questions

Q: Is the frequency drive suitable for every pump type?

A: Yes, it is suitable for all pumps with asynchronous (squirrel cage) AC motors. It can be used with submersible pumps, centrifugal pumps, and deep well pumps.

Q: Can I install a frequency drive on my existing pump?

A: Yes, esular systems can be easily adapted to your existing pump. No structural changes are required.

Q: How long does it take for energy savings to pay for itself?

A: Under average usage conditions, a return on investment is achieved within 1-2 years. In intensive use, this period can drop to 6-12 months.

Q: Does it work in places where there is no internet?

A: Yes, esular systems use GSM infrastructure. It works anywhere there is a GSM signal.

Important Note: The product information and prices given in this article belong to the date the article was published. For current prices and campaigns, please visit the product pages or contact our sales team.