Classification of Carbon Dioxide (CO2) Sensors

There are various types in the classification of carbon dioxide (CO2) sensors, and understanding the types of CO2 sensors helps in the selection phase. Generally, CO2 sensors can be classified as electrochemical, infrared, and photoacoustic according to their working principles. The working principles and general characteristics of each type are explained in the table below:

| Sensor Type | Principle | General characteristics |

| Electrochemical Sensor | Converts carbon dioxide (CO2) concentration into an electrical signal through electrochemical reactions |

|

| Infrared sensor | Measures CO2 concentration by detecting the absorption of specific infrared light wavelengths by Carbon Dioxide (CO2) molecules | Non-dispersive infrared (NDIR) sensor:

|

Dispersive infrared sensor:

| ||

| Photoacoustic Sensor | Measures CO2 concentration by detecting the absorption of light at specific wavelengths by CO2 molecules or the interaction between CO2 molecules and vibration or sound waves. |

|

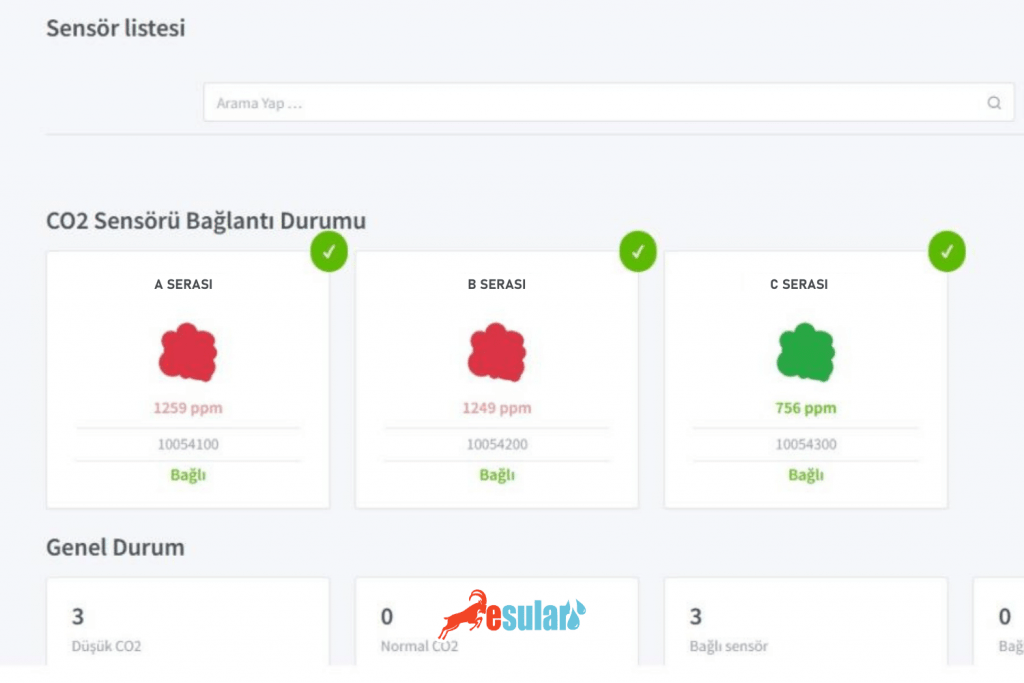

Best Carbon Dioxide (CO2) Sensors for Greenhouses

Factors such as area, cultivated plants, and construction materials are effective in the selection of the best carbon dioxide (CO2) sensors for greenhouses, and the selection can be made according to the actual situation. It is explained in detail in the table below.

Greenhouse Factor | Important Factors | Carbon Dioxide (CO2) Sensor Selection | |

area | Small area (covering an area of <100 square meters) | Measurement range, accuracy | NDIR sensor |

Medium area (covering an area of 100-1000 square meters) | Measurement range, accuracy | NDIR sensor or electrochemical sensor | |

Large area (covering an area of >1000 square meters) | Measurement range, accuracy, power consumption, price | Electrochemical sensor or dispersive infrared sensor | |

Cultivated Plants | Plants with high carbon dioxide (CO2) requirements (such as tomatoes, cucumbers, peppers and other C3 plants and vegetables) | Measurement range, accuracy, power consumption | NDIR sensor |

Plants with low carbon dioxide (CO2) requirements (such as C4 plants and some shade-tolerant plants) | Measurement range, stability | NDIR sensor or electrochemical sensor | |

Construction Materials | Materials with good carbon dioxide (CO2) retention performance (double or multi-layer glass, polycarbonate panels, polyethylene film) | Stability, accuracy | NDIR sensor |

Materials with significant CO2 loss (single-layer glass, transparent plastic film, metal materials) | Accuracy, response time | NDIR sensor or electrochemical sensor | |

Ventilation System | Well-ventilated system (adequate ventilation, even air distribution, good controllability) | Response time, stability, accuracy | NDIR sensor or electrochemical sensor |

Poor ventilation system (inadequate ventilation, uneven air distribution, lack of flexibility in control) | Measurement range, accuracy | NDIR sensor or dispersive infrared sensor | |

Lighting System | Where more artificial light sources are used | Response time | NDIR sensor or electrochemical sensor |

Primarily natural lighting | stability | NDIR sensor or dispersive infrared sensor | |

Control System | Used in conjunction with an automatic control system | Accuracy, response time, stability | NDIR sensor or electrochemical sensor |

No automatic control system | Accuracy, stability | NDIR sensor or dispersive infrared sensor | |

Location | Indoor environment | Accuracy, response time | Photoacoustic sensor, infrared sensor or electrochemical sensor |

outdoor environment | Accuracy, response time, stability, power consumption | infrared sensor or electrochemical sensor | |

While photoacoustic sensors are relatively suitable for indoor environments in the greenhouse, electrochemical sensors depend on some other factors. Among infrared sensor types, NDIR carbon dioxide (CO2) sensors are a commonly used and versatile type. NDIR stands for Non-Dispersive Infrared Gas Analyzer, which uses the absorption properties of infrared light to measure gas concentration. Typically, it consists of an infrared light source, sample chamber, detector, and signal processing circuit. This sensor can measure CO2 concentration quickly and accurately without being affected by other gases. Additionally, it has low power consumption, long-term stability, and is suitable for long-term monitoring in greenhouse environments.

Installation of Carbon Dioxide (CO2) Sensors in Greenhouses

In the installation of carbon dioxide (CO2) sensors in greenhouses, after choosing a suitable carbon dioxide (CO2) sensor, appropriate installation and deployment are necessary to effectively monitor the CO2 concentration in a greenhouse. Correct installation and deployment ensure the accuracy and stability of the sensor, enabling accurate data collection and control in a smart greenhouse system. The following steps can be followed during installation:

- Determining the Sensor Location

The sensor should be placed in the most representative area within the greenhouse, usually on the walls or ceiling at the height of plant growth. This ensures the measurement of the CO2 concentration around the plants. To prevent interference from fresh outside air that could lead to incorrect data within the greenhouse, placing the sensor near ventilation ducts, exhaust pipes, or areas with high human activity should be avoided.

- Mounting the Sensor

Before installing the sensor, it should be ensured that the installation site is level and that screws, expansion tubes, and other materials meet safety requirements. Additionally, some sensors may need to be connected to a power source or other devices. The guidelines provided by the sensor manufacturer should be followed to ensure connections are correct during installation.

- Control Unit Mounting

Connect the sensor to the data collector of the monitoring system to read and transmit CO2 concentration data. The connection method may vary depending on the sensor type; therefore, the sensor's instructions should be followed for guidance.

- Sensor Adjustment

Calibration must be performed before using the sensor to ensure accurate CO2 readings. Some sensors have an automatic calibration feature, while others require manual calibration. The sensor's accuracy and measurement range should be checked before calibration. The calibration process should be carried out according to the instructions provided by the sensor manufacturer, usually involving the use of its software.

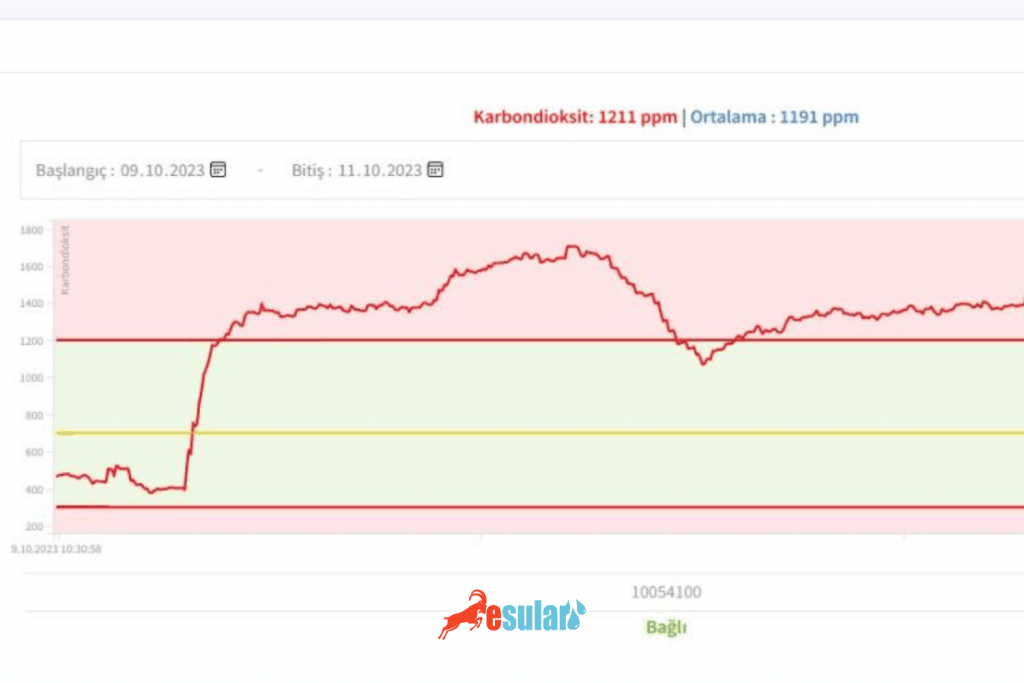

- Setting Sensor Alarms

After installing and connecting the sensor, the monitoring system should be set to start reading CO2 concentration data. Thresholds are usually adjustable; so when the CO2 concentration exceeds or falls below the set thresholds, the system will generate alerts or automatically adjust the CO2 levels in the greenhouse.

- Monitoring and Maintenance of the Sensor

After the sensor is installed, the sensor's measurement results should be monitored regularly. Sensor batteries should be checked and replaced regularly to ensure it works properly.

Creating a carbon dioxide (CO2) monitoring system in a smart greenhouse and choosing a suitable carbon dioxide (CO2) sensor is crucial for monitoring CO2 concentration and supporting plant growth. When choosing a CO2 sensor, factors such as measurement range, accuracy, response time, stability, price, and power consumption should be considered. While the use of versatile NDIR (Non-Dispersive Infrared) CO2 sensors is recommended in greenhouse scenarios, photoacoustic sensors can also be considered for indoor greenhouses. Proper installation and deployment are required to achieve optimum monitoring results with the appropriate CO2 sensor.