Greenhouse Automation Products: Explaining Every System I Use in My Greenhouse

It has been 2 years since I switched to greenhouse automation. During this time, I tested dozens of products, changed some, and upgraded others. In this article, I will explain every product I use in my greenhouse in detail. Along with technical specifications, real performance, advantages, and disadvantages.

Let's get started.

Contents

- Automatic Window Control Systems

- CO₂-Humidity-Temperature Monitoring Sensors

- Smart Valve Control Systems

- Soil Moisture and EC Sensors

- Fertigation (Fertilization) Systems

- Weather Station

1. Automatic Greenhouse Window Control System

Why Did I Need It?

I have 12 windows in my greenhouse. In the manual system, I was waking up at 6 AM every morning to open the windows and closing them at 7 PM. But the problem was this: temperatures would rise suddenly during midday hours, and I wouldn't notice. Plants were getting stressed, and yield was dropping.

One day at noon, I measured 38°C in the greenhouse. That day, I decided to buy an automatic window system.

Technical Specifications

Esular Smart Greenhouse Window Control Panel

- Motor Type: AC asynchronous motor control

- Window Capacity: Single or double window models

- Communication: Wireless LoRaWAN technology

- Control Type: Temperature-based automatic + manual

- Safety: Wind sensor integration

- Power Supply: 220V AC (with transformer)

- Protection Class: IP54 (outdoor resistant)

How Does It Work?

The system works in 3 modes:

1. Automatic Mode: When the temperature exceeds 26°C, the windows open gradually. They open fully at 28°C. They close automatically when the temperature drops.

2. Manual Mode: I can open and close them whenever I want from the mobile application. I control them even when I am in Istanbul.

3. Emergency Mode: When the wind speed exceeds 40 km/h, the system automatically closes the windows. The risk of broken glass is eliminated.

Real Performance

In the first month, I observed the following:

✓ Greenhouse internal temperature fluctuation decreased by 60%

✓ Plant stress dropped significantly

✓ Fuel savings increased by 38% because night heat loss was prevented

✓ Air circulation improved, and the mold fungus problem ended

2. CO₂-Humidity-Temperature Monitoring Sensor

The "Smart Eyes" of My Greenhouse

These sensors are the brain of greenhouse automation. Everything works according to this data. At first, I thought "a sensor that only measures temperature is enough." I was wrong.

Technical Specifications

CO₂ Measurement:

- NDIR (Non-Dispersive Infrared) sensor technology

- Measurement range: 400-10,000 ppm

- Accuracy: ±(30 ppm + 3%)

- Calibration: Automatic, annual manual check recommended

Temperature Measurement:

- Measurement range: -40°C to +125°C

- Accuracy: ±0.2°C

- Response time: 30 seconds

Humidity Measurement:

- Measurement range: 0-100% RH

- Accuracy: ±2% RH

- Durability: Condensation protected

Energy and Communication:

- Solar powered (2W panel)

- Rechargeable lithium battery (backup)

- LoRaWAN protocol

- Range: 10+ km (in open field)

- Battery life: 5+ years

Why is CO₂ Measurement Important?

At first, I thought "what use will CO₂ be to me?" Then I researched:

Photosynthesis and CO₂: Plants use CO₂ for photosynthesis. There is 400 ppm CO₂ in normal air. But in a closed greenhouse, this value rises to 1000-1200 ppm at night (plant respiration) and falls below 300 ppm during the day.

My Experience: After installing the CO₂ sensor, I noticed that between 9-10 AM, the CO₂ level drops to 280 ppm. At these hours, I supplement CO₂ by opening the windows to let in outside air. The result? Tomato yield increased.

How Many Sensors are Needed in a Greenhouse?

This is a critical question. Here are my experiences:

500-1,000 m² greenhouse: 1 sensor is sufficient

1,000-2,500 m² greenhouse: 2-3 sensors are ideal (corners + center)

2,500+ m² greenhouse: 4+ sensors (for micro-climate differences)

I use 4 sensors in my 2,500 m² greenhouse. The north side of the greenhouse is 3-4°C colder than the south side, and humidity is 10% higher. I could only detect this difference with multiple sensors.

Mobile Application Features

Real-Time Monitoring: Data arrives every 5 minutes. I can see it with graphs.

Alarms: Notifications are sent to the phone at critical values:

- Temperature exceeds 30°C → Open window warning

- Humidity exceeds 90% → Ventilation warning

- CO₂ falls below 250 ppm → Supplement required

Historical Data Analysis: I can look at 1-year data. I can see how much energy I spent in which months.

3. Wireless Smart Valve Control System

My Irrigation Revolution Started Here

I used to set irrigation times based on estimation. The "it's hot today, let me water a bit" logic. Sometimes I watered too much (root rot), sometimes too little (plant stress).

The Esular wireless valve control system changed everything. Now soil sensors send the data, and the system makes decisions automatically.

Technical Specifications

Wireless Smart Valve Control Unit

- Valve Capacity: 4 or 8 valve outputs

- Valve Type: 9V latch solenoid valves

- Communication: LoRaWAN (5-10 km range)

- Energy: Solar panel (10W) + rechargeable battery

- Pressure Monitoring: Optional pressure sensor

- Water Meter Integration: Pulse type meters

- Protection: IP68 (waterproof)

- Installation: Field, greenhouse, garden

Irrigation Modes

1. Timer-Based:

The classic method. 20 minutes of irrigation every day at 7:00 AM. Simple but inefficient.

2. Soil Moisture Sensor Triggered:

Automatic irrigation starts when soil moisture falls below 40%. It stops when it reaches 60%. I use this mode; water savings are higher.

3. Weather Adaptive:

Irrigation is canceled if it has rained. Irrigation duration increases if the weather is hot. The smart system adjusts itself.

4. Scenario-Based:

Seedlings for 10 minutes, vegetables for 25 minutes on Monday. Different programs for each zone.

Real Use Scenario

6:30 AM – Automatic Irrigation Start:

Soil moisture sensor shows 38%. The system opens valve number 1. The tomato zone is being irrigated.

6:50 AM – Moisture Reached 58%:

The system closes the valve. Just in time, neither more nor less.

12:00 PM – Second Irrigation Request:

Temperature is 32°C, the soil is drying fast. Moisture dropped to 42%. The system starts the 2nd irrigation.

6:00 PM – Weather Control:

It will rain tomorrow. The system cancels the morning irrigation.

4. Soil Moisture-EC-Temperature Sensors

Understanding the "Language" of the Plant

Plants cannot speak, but the root zone tells everything. Soil moisture, salinity, temperature… Modern greenhouse farming cannot be done without knowing this data.

Esular soil sensors come in 3 different models. I tested them all, and I will explain which one I used and why.

Model 1: Single Level (30 cm)

Technical Specifications:

- Measurement depth: 30 cm

- Parameters: Moisture + Temperature

- Communication: LoRa/LoRaWAN

- Energy: Solar panel + battery

- Battery life: 10 years

- Accuracy: Moisture ±3%, Temperature ±0.5°C

Area of Use:

Pot production, seedling greenhouses, shallow-rooted plants (lettuce, basil)

My Use:

I use 2 of them in my seedling section. Seedlings are already shallow-rooted; 30 cm is sufficient.

Advantages:

- Most affordable model

- Very simple installation

- Ideal for small areas

Model 2: 3 Levels (30-60-90 cm) ⭐ MY CHOICE

Technical Specifications:

- Measurement depths: 30 cm, 60 cm, 90 cm

- Parameters: Moisture + Temperature at 3 levels

- Communication: LoRaWAN

- Energy: Solar panel (5W) + lithium battery

- Battery life: 8-10 years

- Data frequency: Every 15 minutes

Area of Use:

Medium-deep rooted vegetables such as tomatoes, peppers, eggplants, cucumbers

My Use:

I use 6 of these sensors in my tomato greenhouse. It is the model I prefer the most.

Why This Model?

In tomatoes, the root system goes down to a depth of 60-80 cm. With a single-level sensor, you only see surface moisture. But with 3 levels, I learned the following:

✓ Surface (30 cm): Dries fast, daily monitoring

✓ Middle (60 cm): Main root zone, critical level

✓ Deep (90 cm): Water accumulation control

Real Event: One day, the surface moisture appeared to be 45% (normal). But at 60 cm depth, it was 28% (dry), and at 90 cm, it was 75% (very wet). In other words, I had watered the surface, but the middle root zone remained thirsty, and water had accumulated at the bottom. I detected the drainage problem with this sensor.

Advantages:

- You see the entire root profile

- Irrigation timing is very precise

- Drainage problems are detected early

- Perfect price/performance balance

Model 3: 4 Levels + EC (30-60-90-120 cm) 🏆 PREMIUM

Technical Specifications:

- Measurement depths: 30, 60, 90, 120 cm

- Parameters: Moisture + EC (salinity) + Temperature

- EC measurement range: 0-8 dS/m

- Communication: LoRaWAN

- Energy: Large solar panel (10W) + capacitor

- Data frequency: Every 10 minutes

Area of Use:

Professional production, export quality, greenhouses with fertigation systems

My Use:

I use 2 of them in the special section where I produce for export. Critical for fertilization.

What is EC (Electrical Conductivity)?

EC measures the salt concentration in the soil. In other words, it shows how much fertilizer has accumulated.

Ideal EC Values:

- Tomato: 2.0-3.5 dS/m

- Cucumber: 1.7-2.5 dS/m

- Pepper: 1.5-2.5 dS/m

If EC is too high: The plant cannot take in water (salt burn), leaves turn yellow

If EC is too low: The plant is hungry, development is slow

Real Experience: I keep the EC at 3.2 dS/m for tomatoes. Fruit quality is A+, sugar content is high. But 1 week before export, I drop the EC to 2.5 (more water), which increases the fruit size.

Advantages:

- Precise fertilization tracking

- Deep drainage control thanks to 120 cm depth

- Essential for professional production

- Reduces chemical use

5. Fertigation (Smart Fertilization) Systems

Fertilizer is No Longer "Pouring" but "Feeding"

I used to fertilize like this: 10 kg of fertilizer once a week, mix it with water, and pour. The result? Sometimes the plant got too much fertilizer (burning), sometimes too little (no development), always a waste of money.

The Esular Smart Agro fertigation system taught me how to fertilize precisely.

Smart Agro Mini – Entry Level

Technical Specifications:

- Control of 2 fertilizer tanks

- pH and EC measurement/control

- Capacity: 1000 L/hour irrigation

- Communication: GSM/WiFi

- Pump: Peristaltic (acid-base resistant)

- Automation: Simple scenario

Area of Use:

500-1,500 m² small-medium greenhouses, hobby production

How Does It Work?

- Target pH: 6.0, Target EC: 2.5 dS/m

- Irrigation water arrives with pH 7.2 and EC 0.4

- The system automatically adds acid → pH drops to 6.0

- The system automatically adds fertilizer → EC rises to 2.5

- The ready nutrient solution goes to the plants

Results:

✓ Fertilizer savings: 22% (use at full dose)

✓ Plant development: 18% faster

✓ Fruit quality: More homogeneous

✓ Labor: No manual mixing

Smart Agro Max – Professional System ⭐

Technical Specifications:

- Control of 4 fertilizer tanks

- Advanced pH + EC sensors (industrial)

- Capacity: 2000 L/hour

- Communication: LoRaWAN + GSM/WiFi (dual backup)

- Pump: Industrial peristaltic (50,000 hours life)

- Automation: Advanced scenario, timer

- Reporting: PDF output, Excel export

Area of Use:

1,500-5,000 m² medium-large greenhouses, commercial production

Advanced Features:

1. Automation According to Vegetation Period:

- Seedling period: EC 1.8, more nitrogen

- Flowering: EC 2.3, more phosphorus

- Fruit period: EC 2.8, more potassium

I programmed the periods into the system; it switches automatically.

2. Weather Integration:

It lowers the EC on rainy days (the plant takes in less fertilizer) and raises it on sunny days.

3. Detailed Reporting:

A PDF report arrives every month:

- Total fertilizer use (kg)

- Daily EC-pH graphs

- Cost analysis

Smart Agro Maxi – Industrial Solution 🏆

I haven't used this model yet, but I saw it in a neighbor's 8,000 m² greenhouse.

Technical Specifications:

- 4 fertilizer tanks + expandable (up to 8 tanks)

- High precision sensors (±1% EC, ±0.05 pH)

- Capacity: 4000 L/hour

- SCADA integration

- Expert system software (AI supported)

- 24/7 priority technical support

Area of Use:

5,000+ m² large enterprises, cooperatives

Features:

- AI calculates plant nutrition models

- Comparison with previous years' data

- Automatic ordering system (orders from supplier when fertilizer runs out)

- Multi-greenhouse management (10 greenhouses from a single center)

6. Weather Station – Extra-Greenhouse Monitoring

You Cannot Manage the Inside Without Knowing the Outside

The weather station measures the weather conditions outside the greenhouse. You might say, "I already check the weather forecast." But the general weather and the situation on your land are different.

Esular Weather Station

Measurement Parameters:

- Outdoor air temperature (±0.3°C)

- Outdoor air humidity (±3% RH)

- Wind speed and direction

- Precipitation amount and intensity

- Solar radiation (solar energy)

- Atmospheric pressure

- Dew point (calculated)

Communication: LoRaWAN + GSM

Energy: Solar panel (20W) + large battery

Mounting: 3-4 meter pole

Why is it Necessary?

1. Frost Risk Prediction:

With dew point calculation, if there is a frost risk at night, early morning heating is activated.

2. Disease Early Warning:

High humidity + low temperature = risk of mold fungus. The system warns, and I take precautions.

3. Irrigation Optimization:

If solar radiation is high, the plant evaporates more water, and the system increases the irrigation duration.

4. Wind Safety:

When the wind exceeds 50 km/h, all windows close automatically.

Real Event:

In March, an alarm came to my phone at 5 AM: "Dew point 2°C, frost risk!" I turned on the heating immediately. Frost damage occurred in the neighboring greenhouse, but not in mine. Thanks to the weather station.

Which Products Should You Use Together?

Entry Level (500-1,000 m²)

Minimum System:

- 1 Window Control Panel

- 2 CO₂-Humidity-Temperature Sensors

- 1 4-Valve Control Unit

- 2 Soil Moisture Sensors (3 levels)

Medium Level (1,500-3,000 m²)

Recommended System:

- 2 Window Control Panels (multi-window)

- 4 CO₂-Humidity-Temperature Sensors

- 1 8-Valve Control Unit

- 4 Soil Moisture-EC Sensors (4 levels)

- 1 Smart Agro Mini Fertigation

- 1 Weather Station

Advanced Level (3,000+ m²)

Professional System:

- 4 Window Control Panels

- 8 CO₂-Humidity-Temperature Sensors

- 2 8-Valve Control Units (16 valves)

- 8 Soil Moisture-EC Sensors

- 1 Smart Agro Max Fertigation

- 1 Weather Station (professional)

- SCADA software integration

Frequently Asked Questions

Are all products managed through the same application?

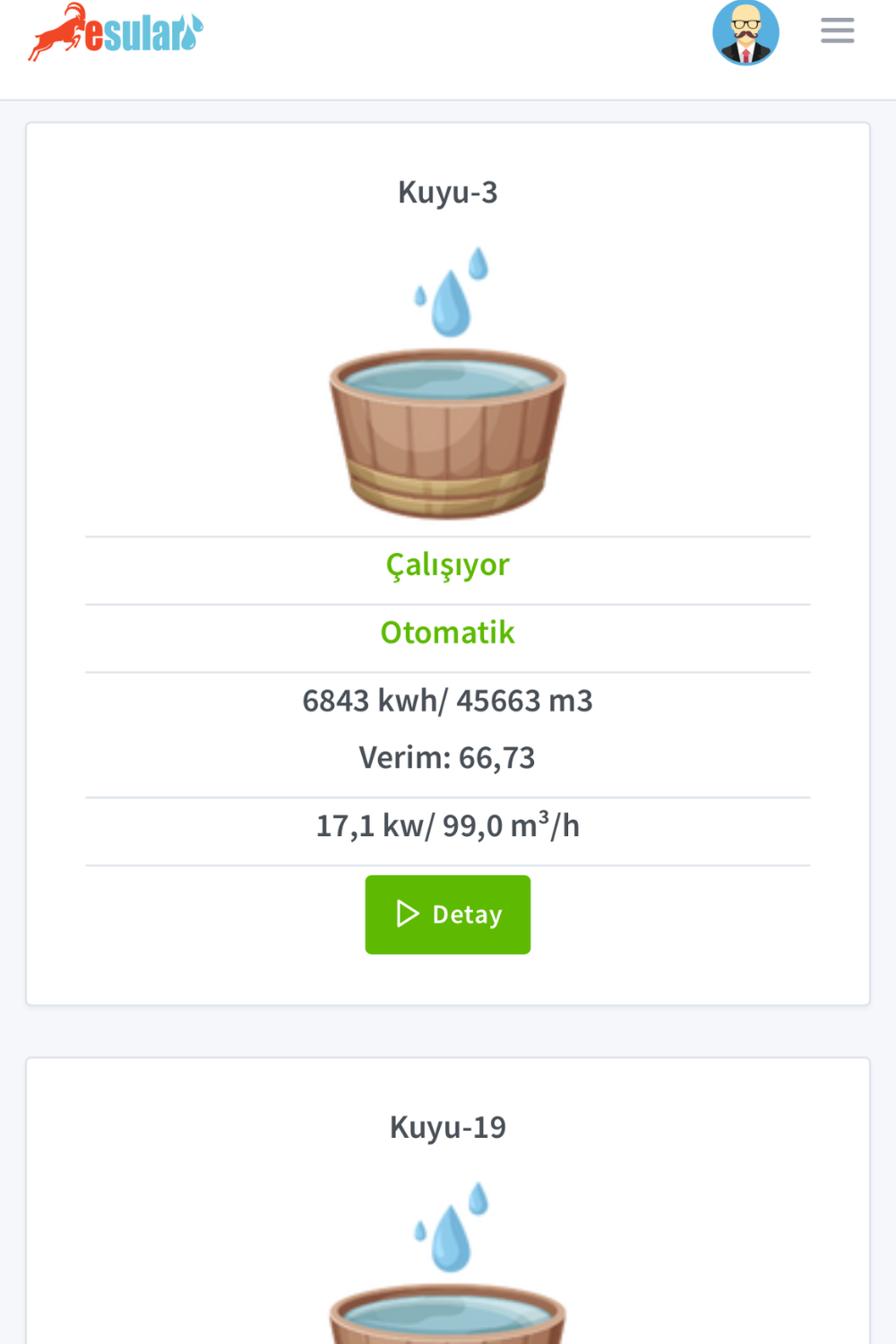

Yes. The Esular mobile application gathers all devices on a single platform. Sensors, valves, windows, fertilization… Everything on one screen.

Can the wireless system be interrupted?

I have been using it for 2 years and haven't experienced any problems. The system can also work in offline mode. The last programs continue.

How long does installation take?

- Basic system (2-4 products): 1 day

- Medium system (5-10 products): 2-3 days

- Full system (10+ products): 4-7 days

Is there a maintenance cost?

Annual Maintenance:

- Sensor calibration

- Spare parts: When necessary

Does it work without internet?

Yes. The systems work with GSM. No Internet is needed; a cell phone signal is sufficient.

Final Words: Summary of 2 Years of Experience

I started greenhouse automation 2 years ago. At first, I only bought window control. Then sensors, irrigation, fertilization… Each product required the next one.

Do I recommend Esular products? Definitely yes.

Greenhouse farming is no longer a "labor" job but a "management" job. Smart systems work, and I control them.

⚠️ Price and Campaign Warning: All prices and technical specifications mentioned in this article are valid as of the date of publication (October 2025). Product prices, stock status, and campaigns are subject to change without notice. For current prices, please visit the Esular Store page or contact the sales team. The mentioned savings figures are average values and may vary according to greenhouse size, usage pattern, and regional differences.