Agricultural Solenoid Valve Selection: Plastic Composite or Cast Type?

Solenoid valves, one of the most critical components of smart irrigation systems, are electromechanical devices that electronically control water flow. In agricultural automation projects, choosing the right valve directly affects the system's performance, cost, and lifespan. In this article, we examine in detail which one should be preferred for which applications by comparing the advantages and disadvantages of plastic composite and cast type solenoid valves.

What is a Solenoid Valve and How Does It Work?

A solenoid valve is an automatic valve system that controls the passage of water, air, or other fluids using an electromagnetic coil. The basic working principle is quite simple: when electrical energy is supplied to the coil, the resulting magnetic field moves the piston inside, and the valve opens or closes.

In agricultural applications, solenoid valves are used as follows:

Drip Irrigation Systems: Ensures that each irrigation line is controlled individually. Different plant zones can be irrigated at different times.

Sprinkler Systems: Provides regional irrigation control in sprinkler and pivot systems.

Greenhouse Automation: Provides precise control in greenhouse irrigation and fertilization systems.

Pump Control: Regulates the opening and closing of main irrigation pumps.

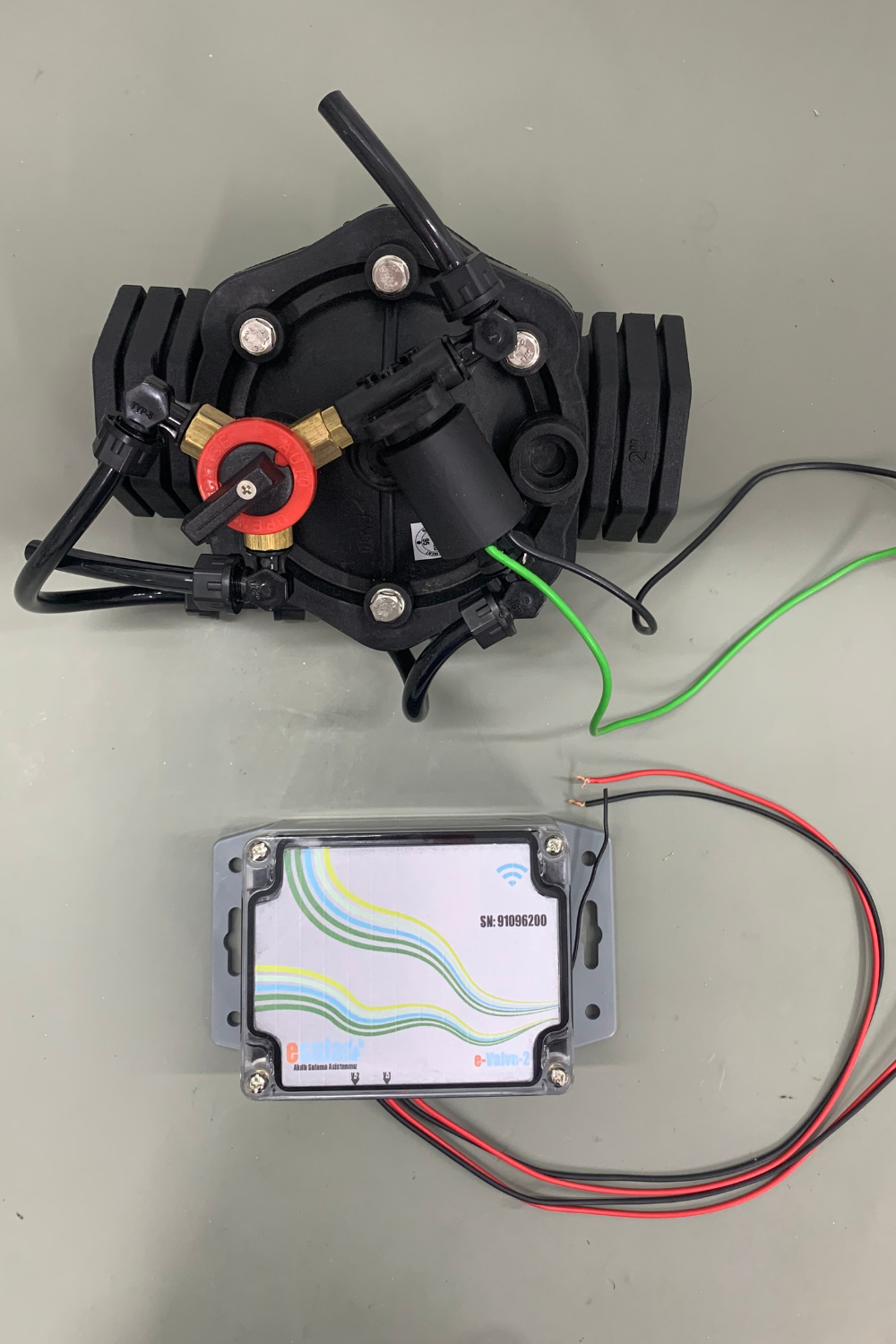

Esular solenoid valves operate with 9-12V DC Latch or 24V AC electrical options. Especially 9V Latch technology is an ideal solution for wireless smart irrigation systems as it only consumes energy during opening and closing moments.

Plastic Composite Solenoid Valves: Features and Advantages

Plastic composite body solenoid valves are becoming increasingly common in modern agricultural irrigation systems. The Esular Threaded Hydraulic Solenoid Valve series is the most popular representative of this category.

Technical Features of Plastic Composite Valves

Material Structure: Produced from high-strength engineering plastic and fiber-reinforced composite blend. This material shows excellent resistance to corrosion.

Pressure Resistance: Esular plastic composite valves withstand pressure up to 10 bar. This value is sufficient for most agricultural irrigation applications.

Diameter Options: Offers diameter options ranging from 3/4" (20mm) to 2 1/2" (63mm). Ideal for small and medium-sized irrigation lines.

Weight: Much lighter than metal valves. A 1" diameter plastic valve weighs approximately 300-400 grams.

Mounting Type: Usually installed with threaded connections (BSP or NPT standards). Offers quick and easy installation.

Advantages of Plastic Composite Valves

1. Corrosion Resistance: Plastic material is completely resistant to rusting. It works smoothly even in irrigation water containing salt water, water with fertilizer, or chemical additives. It provides a great advantage in agricultural lands in coastal areas and salty soils.

2. Low Cost: Production cost is significantly lower than metal valves. It reduces the total cost, especially in projects where a large number of valves must be used. When 50 valves are used in a 100-decare field, the plastic option provides approximately 30-40% cost savings.

3. Lightness: Installation and maintenance work is much easier. Even a technician working alone in the field can easily carry and install it. It provides a safety advantage in above-tree installations or installations in high places.

4. Electrical Insulation: Since the plastic body does not conduct electrical current, it is safer against electrical leakages. Does not require grounding.

5. Low Pressure Loss: Since its internal structure is optimized, it creates minimum pressure loss in water flow. Increases efficiency in low-pressure irrigation systems.

6. Quiet Operation: During opening and closing, no impact sound occurs as in metal valves.

Disadvantages of Plastic Composite Valves

1. Limited Pressure Capacity: Withstands a maximum of 10 bar pressure. Cannot be used in very high-pressure systems.

2. UV Sensitivity: Plastic material may weaken if exposed to sunlight for a long time. In open fields, installation inside a box or in the shade is recommended for sun protection.

3. Mechanical Impact Sensitivity: More sensitive to hard impacts than metal valves. There is a risk of breakage in case of impact with a plow or other agricultural tools.

4. Temperature Limitations: Generally operates between -10°C and +60°C. Performance may decrease in extreme hot or cold conditions.

Cast Type Solenoid Valves: Features and Advantages

Cast type solenoid valves are valves usually with cast iron or cast aluminum bodies designed for heavy-duty applications. The Esular Flanged Hydraulic Solenoid Valve series is included in this category.

Technical Features of Cast Type Valves

Material Structure: Produced from high-quality cast iron, ductile iron, or cast aluminum alloy. It has a strong and durable structure.

Pressure Resistance: Easily withstands pressures of 10 bar and above. Some models can work up to 16 bar.

Diameter Options: Esular flanged valves are offered in large diameters such as 3" (80mm), 4" (100mm), and 6" (150mm). Designed for applications requiring high flow rates.

Weight: Much heavier than plastic valves. A 3" diameter flanged cast valve can weigh 8-12 kg.

Mounting Type: Flange connection is used. Requires installation with bolts and gaskets. Professional installation recommended.

Advantages of Cast Type Valves

1. High Pressure Capacity: Operates safely at pressures of 10 bar and above. Ideal for main irrigation lines and high-pressure pumping systems.

2. High Flow Capacity: Thanks to its large diameters, it can carry water at very high flow rates. A 6" flanged valve can provide 400-500 cubic meters of water passage per hour.

3. Mechanical Durability: Extremely resistant to impacts, crushing, and mechanical strain. Works smoothly for many years in harsh terrain conditions.

4. Wide Temperature Range: Can work safely between -20°C and +80°C. Maintains its performance even in extreme climate conditions.

5. Long Life: Has a lifespan of 15-20 years and above when properly maintained. Return on investment is very good in the long run.

6. Compliance with Industrial Standards: Flange connections comply with international standards (PN10, PN16, etc.). Compatible with all standard pipe systems.

Disadvantages of Cast Type Valves

1. High Cost: 2-3 times more expensive than plastic valves. Initial investment cost is high.

2. Weight: Usually requires at least 2 people for installation. Transport and assembly are difficult. Special lifting equipment may be required.

3. Corrosion Risk: There is a risk of rusting, especially in cast iron valves. Internal and external surface protection is required in salty water or acidic environments. Regular paint maintenance should be performed.

4. Complex Installation: Technical knowledge such as suitable gasket selection and bolt tightening torque is required for flange installation. Incorrect installation can cause leaks.

5. Freezing Risk at Low Temperatures: There is a risk of cracking when the metal body freezes. The system must be drained or insulated in winter months.

Detailed Comparison Table

| Feature | Plastic Composite Valves | Cast Type Valves |

|---|---|---|

| Diameter Range | 3/4" – 6" (20-150mm) | 3" – 6" (80-150mm) |

| Maximum Pressure | 10 bar | 16 bar |

| Weight (1" / 3") | 300-400 grams | 8-12 kg |

| Corrosion Resistance | Excellent (Stainless) | Medium (Requires maintenance) |

| Ease of Installation | Very Easy (Threaded connection) | Difficult (Flange mounting) |

| Price Range | Low-Medium | High |

| Lifespan | 8-12 years | 15-20 years |

| Temperature Range | -10°C / +60°C | -20°C / +80°C |

| UV Resistance | Medium (Requires protection) | Excellent |

| Mechanical Durability | Medium | Very High |

| Flow Capacity | Low-Medium | High-Very High |

| Maintenance Need | Minimum | Regular |

Which One Should Be Preferred in Which Application?

Applications Where Plastic Composite Valves Are Ideal

1. Drip Irrigation Systems: Plastic valves show excellent performance in drip irrigation lines operating at low flow and medium pressure. Cost advantage is important when a separate valve is used for each field block.

2. Greenhouse Irrigation: Corrosion resistance is critical in areas with salt water risk inside the greenhouse. Plastic valves work long-lastingly in this environment.

3. Small and Medium-Sized Projects: Plastic valves are the ideal solution for projects with budget constraints on lands between 10-50 decares.

4. Garden and Park Irrigation: In landscaping applications, low pressure and medium flow are sufficient for lawn irrigation systems.

5. Vegetable Farming: Plastic valves are widely preferred in vegetable cultivation such as tomatoes, peppers, and eggplants.

6. Coastal Regions: Corrosion problems are not experienced in regions with salt water risk.

Applications Where Cast Type Valves Are Ideal

1. Main Irrigation Lines: Cast valves are a must in main distribution lines operating at high pressure and high flow. They must be used at the main inlet of 100+ decare lands.

2. Center Pivot Systems: Large-diameter cast valves are used in mobile pivot irrigation systems because high flow and pressure are required.

3. Pump Outlet Lines: Valves resistant to pressure fluctuations are required at the outlet of well or pond pumps.

4. Industrial Agriculture Projects: In the projects of large-scale agricultural companies, long life and reliability are priority.

5. Fruit Orchards: Strong valves are required in apple, pear, and cherry orchards where high-pressure sprinkler irrigation is performed.

6. Water Source Control: High-capacity valves are used at the inlet/outlet points of dams, ponds, or large water tanks.

Hybrid Solution: Using Both Together

In real-life projects, the most economical and efficient solution is usually to combine both valve types:

Main Line: Cast type large diameter flanged valve (3" or 4")

Sub-lines: Plastic composite threaded valves (1" or 1.5")

This approach both optimizes cost and uses the most appropriate technology at every point. For example, in a 100-decare cotton field:

- Pump outlet and main line: 1 unit 4" flanged cast valve

- 4 main block inlets: 4 units 2" plastic composite valves

- 16 sub-sections: 16 units 1" plastic composite valves

With this configuration, both reliability and cost balance are achieved.

Esular Solenoid Valve Products

Esular offers a wide range of products in both valve categories. All our valves work fully compatible with wireless smart irrigation systems with 9V Latch or 24V AC electrical options.

Plastic Composite Valve Options

https://store.esular.com/disli-hidrolik-selenoid-vana-4

Esular Threaded Hydraulic Solenoid Valve Features:

- 6 different diameter options between 3/4" and 3"

- 10 bar maximum working pressure

- Plastic composite body – full corrosion resistance

- 9V Latch low energy consumption

- Threaded connection – easy installation

- Suitable for drip irrigation and sprinkler systems

Cast Type Valve Options

Esular Flanged Hydraulic Solenoid Valve: Designed for large diameter, high pressure, and high flow applications. Examine product details

Features:

- 3", 4", and 6" diameter options

- Pressure resistance up to 16 bar

- Reinforced cast body

- Flange connection (PN10/PN16 standards)

- High flow capacity

- Ideal for main irrigation lines

Criteria to Consider When Choosing a Solenoid Valve

When making the right valve selection, be sure to evaluate the following factors:

1. Pressure Values: Determine the operating pressure and maximum pressure of your system. The valve should have a resistance at least 20% higher than the maximum pressure.

2. Flow Requirement: Calculate the required water flow for each line. The valve diameter should provide the desired flow with minimum pressure loss.

3. Water Quality: If you are using salty, fertilized, or chemically additive water, choose a valve with high corrosion resistance.

4. Energy Source: Choose 24V AC if there is an electrical grid, and 9V Latch valves if you are using a wireless system.

5. Installation Conditions: IP68 protection is important for underground installation, and UV resistance is important for open installation.

6. Budget: Evaluate the initial investment cost and long-term operating cost together.

7. Maintenance Capacity: If you do not have a technical team that can perform regular maintenance, choose valves that require minimum maintenance.

Solenoid Valve Maintenance and Life Extension Tips

To extend the life of both plastic and cast type valves:

For Plastic Valves:

- Protect from sunlight, install inside a valve box if possible

- If there is a risk of freezing in winter months, drain the system

- Prevent dirty water passage by using a filter

- Check gaskets and O-rings once a year

- Take protective measures against hard impacts

For Cast Valves:

- Check for external surface rust once a year, apply paint maintenance if necessary

- Regularly check flange gasket and bolt tightness

- Prevent coil connections from absorbing moisture

- Perform test runs at the beginning and end of the season

- Completely drain the water inside before winter

Real Project Examples

Example 1: Plastic Valve Application in a 30-Decare Tomato Greenhouse

Esular 1" plastic composite valves were used in a 30-decare tomato greenhouse in Antalya. In the greenhouse divided into 6 separate zones, 1 valve was installed for each zone. Since fertilized water was used, corrosion resistance was critically important. The system, which has been working smoothly for 3 years, has provided 35% water savings.

Costs:

- 6 units of 1" plastic valves

- Wireless control system

- Total valve cost: 40% savings compared to cast because plastic was chosen

Example 2: Hybrid Solution in a 200-Decare Cotton Field

A hybrid system was established in a 200-decare cotton field in Şanlıurfa:

- Main line: 1 unit 4" flanged cast valve

- 4 main blocks: 4 units 2" plastic valves

- 16 sub-sections: 16 units 1" plastic valves

With this configuration, both reliability and cost optimization were achieved. The system has been working smoothly for 5 years.

Future Trends: Smart Solenoid Valves

Agricultural automation is developing rapidly. Innovations we will see in solenoid valves in the future:

Integrated Sensors: Flow sensor, pressure sensor, and temperature sensor integrated into the valve. The valve will not only open and close but also collect data.

AI-Powered Control: Artificial intelligence algorithms will determine the most optimal irrigation time and duration by analyzing historical data.

Solar-Powered Models: Completely independent valve systems that generate their own energy.

Modular Structure: Modular valve designs that can be customized according to needs and easily repaired.

As Esular, we follow these trends closely and our R&D studies continue.

Conclusion and Recommendations

Plastic composite and cast type solenoid valves are technologies that each provide superiority in different applications. The right choice depends on the characteristics of your project:

Plastic Composite Valves: Ideal for small-medium scale projects, drip irrigation, greenhouse applications, areas with salt water risk, and cost-oriented solutions.

Cast Type Valves: Should be preferred for large-scale projects, high pressure and flow, main irrigation lines, long life expectancy, and industrial applications.

Hybrid Approach: The smartest solution for most projects is to use cast valves on main lines and plastic valves on sub-lines.

As Esular, we offer a wide range of products in both technologies. Our expert team will be happy to assist you in choosing the most suitable valve for your project.

Price Warning: The price comparisons mentioned in this article are based on the list prices at the date of publication. Please visit the product pages for current prices and campaigns. Prices may vary.

Let Us Help You Choose the Right Solenoid Valve for Your Project

The Esular expert team will help you determine the most suitable valve system according to your field size, soil structure, plant type, and budget. Contact us for free project consultancy.

📞 Phone: 0850 303 49 91

📧 E-mail: info@esular.com. View All Valve Options

Related Content:

- 📖

- 📖

- 📖

- 📖