Future Food Security: Smart Automation in Vertical Farming and Hydroponic Systems

While the world population is projected to exceed 10 billion in 2050, food security is becoming one of the most critical issues facing humanity. Climate change, decreasing agricultural lands, and water scarcity make traditional agricultural methods insufficient. At this point, vertical farming and hydroponic systems stand out as technologies that will revolutionize future food production.

Esular, as Turkey's leading manufacturer of smart agricultural technologies, is by the side of farmers with wireless sensor and automation solutions specifically designed for vertical farming and hydroponic systems. In this article, we will examine in detail what vertical farming and hydroponic systems are, their advantages, and how Esular plays a critical role in these systems.

What is Vertical Farming? The Future of Modern Food Production

Vertical farming is an innovative agricultural method where plants are grown in vertical layers instead of traditional horizontal fields. Mostly carried out in indoor environments and fully controlled climate conditions, this system aims to achieve maximum yield with minimum area usage.

Key features of vertical farming:

Layered Production System: Plants are grown on multi-story shelves or in towers. Each layer has an optimized LED lighting and nutrient delivery system. Thanks to this structure, 10 times more production can be made on the same area compared to traditional agriculture.

Controlled Environment Agriculture: All environmental parameters such as temperature, humidity, CO2 level, and light intensity are precisely controlled. This control ensures uninterrupted production throughout the year and a guarantee of the same quality product every time.

Urban Production Opportunity: Vertical farming facilities can be established in empty buildings in city centers, in attics, and even in old factory areas. In this way, food reaches consumers in the shortest time and in its freshest form.

Closed System: Production is carried out completely independently of outdoor weather conditions, pests, and diseases. Pesticides and agricultural chemicals are not needed.

Hydroponic Systems: High-Efficiency Production Without Soil

Hydroponic systems are a soilless agricultural method where plants are grown without using soil, only in water containing nutrient solutions. In this system, plants reach the nutrients they need directly from their roots and grow rapidly without energy loss.

The working principle of hydroponic systems is quite simple: Plants are exposed to a specially prepared nutrient solution. This solution contains macro-nutrients such as nitrogen, phosphorus, and potassium, as well as micro-nutrients such as iron, zinc, and manganese. The roots come into contact with this solution continuously or periodically, and the plant receives all the necessary nutrients.

Types of hydroponic systems:

NFT (Nutrient Film Technique): A thin nutrient film flows continuously over the plant roots. It is the most commonly used hydroponic method and is especially ideal for leafy vegetables.

DWC (Deep Water Culture): Plants grow with their roots completely submerged in the nutrient solution. Oxygen is provided by air pumps.

Drip Irrigation Hydroponics: The nutrient solution is delivered to the plant roots via a drip system. Esular's smart irrigation systems work perfectly in this method.

Aeroponic System: Plants hang in the air and the nutrient solution is sprayed onto their roots. It is the most advanced and least water-consuming method.

Esular Smart Sensor Solutions in Vertical Farming and Hydroponic Systems

The success of vertical farming and hydroponic systems depends on the precise control of environmental parameters. Esular guarantees optimal growth conditions with wireless sensor and automation solutions specifically designed for these systems.

pH and EC Measurement: The Heart of Hydroponic Systems

The most critical parameters in hydroponic systems are pH and EC (electrical conductivity) values. While pH indicates the acidity or alkalinity of the nutrient solution, EC measures the nutrient concentration.

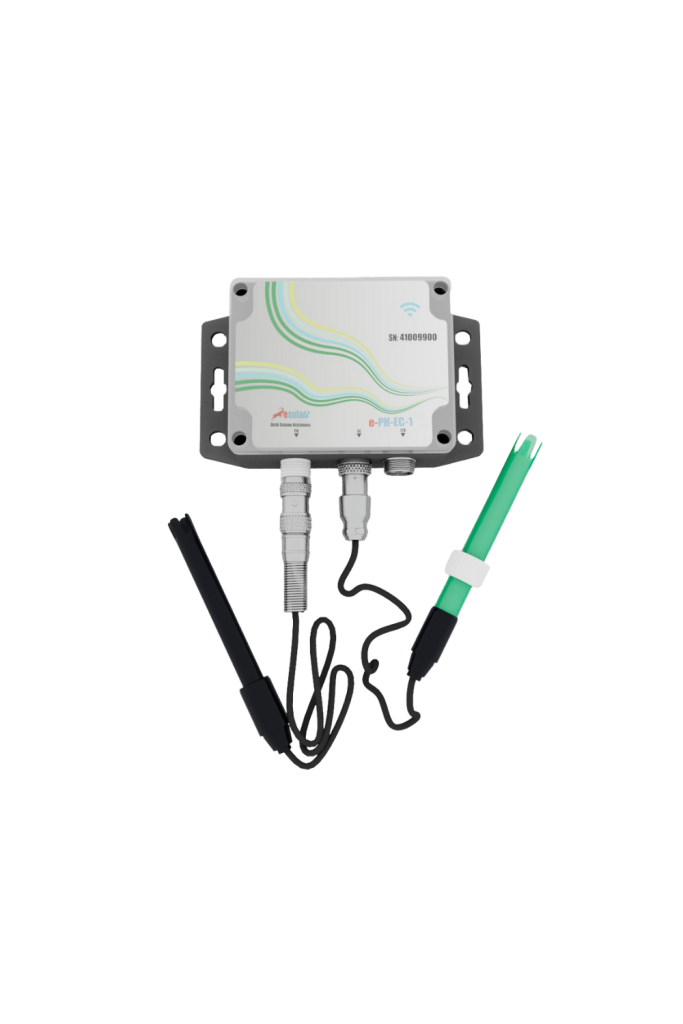

Esular Wireless pH-EC Sensor provides precise and continuous measurement in hydroponic systems:

Double Point Calibration: The sensor measures precisely in the range of pH 0.00-14.00 and EC 0.00-19.99 mS/cm. Accuracy is guaranteed with double point calibration.

Wireless Data Transmission: Measurement data is transmitted to the central system with LoRa technology. Since it does not require cables, installation is easy and maintenance costs are minimal.

Automatic Alarm System: You receive instant notifications when pH or EC values go outside the determined limits. In this way, nutrient imbalances are corrected immediately.

Operation During Power Outage: Thanks to the internal rechargeable battery, it continues to take measurements for up to 7 days during power outages.

Why is pH-EC Control So Important? Plants can only absorb nutrients within certain pH ranges. The ideal pH range for most plants is between 5.5-6.5. When pH goes outside this range, nutrient lockout occurs and plants experience nutritional disorders. The EC value indicates the nutrient concentration - very low EC causes nutritional deficiency, while very high EC causes salinity stress.

https://store.esular.com/kablosuz-pilli-ph-ec-sicaklik-sensoru-smart-serisi-0

CO2 Control: Increase Photosynthesis Efficiency

One of the biggest needs of plants grown in indoor environments is carbon dioxide. CO2 levels, which are approximately 400 ppm in the natural environment, can be increased up to 1000-1500 ppm in controlled environments to significantly increase the rate of photosynthesis and thus yield.

Esular Wireless CO2-Humidity-Temperature Sensor plays a critical role in vertical farming and greenhouse systems:

NDIR CO2 Measurement Technology: Precise CO2 measurement is performed in the 0-5000 ppm range using a professional-grade NDIR (Non-Dispersive Infrared) sensor.

Triple Parameter Monitoring: CO2, humidity, and temperature are measured in a single sensor. In this way, all critical parameters are monitored at the same time.

Solar-Powered Operation: Provides continuous operation for up to 5 years with an integrated solar panel and rechargeable battery. Maintenance-free.

IP65 Waterproofing: Safely used in high-humidity greenhouse and vertical farming environments.

Benefits of CO2 Enrichment: Research shows that increasing CO2 levels to 1000-1200 ppm provides a 20-30 percent yield increase in vegetables such as lettuce, tomatoes, and peppers. Especially in vertical farming systems, CO2 supplementation is mandatory because there is no natural ventilation.

Climate Control: Temperature and Humidity Management

In vertical farming and hydroponic systems, ambient temperature and humidity levels are of vital importance for plant health. Each plant species has specific temperature and humidity requirements for optimal growth.

Esular Wireless Climate Sensors provide perfect climate control in greenhouse and vertical farming facilities:

High Precision: Offers ±0.3°C precision in temperature measurement and ±2% in humidity measurement. This precision is the required standard for professional production.

Multi-Point Monitoring: You can control climate homogeneity by placing sensors at different points in large facilities. All sensors are wirelessly connected to the central system.

Automatic Ventilation Integration: Sensor data can automatically control ventilation fans, heaters, and humidification systems.

Different Day-Night Settings: Different temperature and humidity targets can be determined for day and night according to the needs of plants in different cycles.

Example Application – Lettuce Cultivation: Ideal conditions for lettuce are a temperature range of 18-22°C and a humidity range of 50-70 percent. These parameters are constantly monitored and automatically adjusted with Esular sensors. When the temperature exceeds 24°C, cooling fans are activated, and when the humidity falls below 40 percent, the humidification system operates.

Substrate and Ambient Humidity Measurement

In hydroponic systems using solid media (cocopeat, perlite, vermiculite, etc.), substrate moisture is of critical importance. Substrate that is too dry causes plant stress, while substrate that is too wet causes root rot.

Esular Wireless Soil/Substrate Moisture Sensors provide precise moisture measurement in soilless agricultural environments:

Multi-Stage Measurement: Models capable of measuring at 1-4 stage depths are available. Moisture monitoring is performed at different levels of pots or growing trays.

EC Measurement Option: In some models, substrate EC measurement is also performed. In this way, nutrient concentration can also be monitored.

Long-Lasting Carbon Electrodes: Carbon fiber tips resistant to rusting and corrosion are used. It works for years without requiring maintenance.

Wireless and Battery Powered: Offers 3-5 years of battery life. Thousands of pots can be monitored simultaneously in large facilities.

https://store.esular.com/kablosuz-pilli-toprak-nem-sensoru-0

Advantages of Vertical Farming and Hydroponic Systems

Vertical farming and hydroponic systems offer many significant advantages compared to traditional agriculture. These advantages are of vital importance in terms of food security and sustainable agriculture.

Water Saving: Protect the Most Precious Resource

Hydroponic systems provide incredible savings in water use. Compared to traditional agriculture, water savings of up to 90 percent are possible. Most of the water is recycled and reused.

Real Figures: While approximately 250 liters of water are spent to produce 1 kg of lettuce in traditional soil agriculture, this amount drops to only 20 liters in a hydroponic system. With Esular's smart irrigation and measurement systems, this saving rate can be increased even further.

Water Quality Control: The water used in hydroponic systems is continuously monitored with Esular pH-EC sensors. Nutrient concentration is optimized and water waste is minimized.

Area Efficiency: More Production from Less Space

Vertical farming allows for 10-20 times more production on the same ground area compared to traditional agriculture. On a 100-square-meter area, a planting area of 1000-2000 square meters can be created thanks to layers.

Urban Farming Opportunity: Empty buildings, attics, or parking areas in city centers can be converted into vertical farming facilities. Food is produced at the point closest to the consumer.

Transport Cost and Carbon Footprint: Thanks to local production, there is no need to transport products for miles. Carbon emissions are reduced and products reach the consumer fresher.

Year-Round Production: No Seasonal Limitation

Thanks to controlled environment agriculture, uninterrupted production is carried out throughout the year. It is not affected by negative factors such as outdoor weather conditions, frost, hail, or extreme heat.

With Esular Climate Control Systems, a guarantee of the same quality product every season is provided. Tropical plants can be grown even in winter months.

No Pesticide and Chemical Use

In closed systems, pests and diseases are at a minimum level. Since there are no soil-borne diseases, there is no need for fungicide use. Harmful insects cannot enter the controlled environment.

Organic Certification Advantage: Products grown in these systems where no chemicals are used are suitable for obtaining organic agriculture certification and can be sold at high prices.

Fast Growth and High Yield

In hydroponic systems, plants reach nutrients directly without having to search for them in the soil. In this way, they save energy and focus on growing.

Yield Comparison:

- Lettuce: 60-70 days in traditional agriculture, 30-35 days in hydroponics

- Tomato: 4-5 kg/m² in soil, 15-20 kg/m² in hydroponics

- Strawberry: 1-2 kg/m² in soil, 5-7 kg/m² in hydroponics

Challenges and Solutions Encountered in Vertical Farming and Hydroponic Systems

Like every new technology, vertical farming and hydroponic systems involve some challenges. However, these challenges can be overcome with the right equipment and automation.

Energy Consumption Problem

Challenge: LED lighting and climate control systems consume high energy. This can increase operating costs.

Esular Solution:

- Solar-powered sensors and control systems

- Energy-efficient LED lighting integration

- Electricity is used at night tariffs with smart timing systems

- Real-time energy tracking and optimization

Initial Cost

Challenge: Vertical farming facility establishment requires a higher investment compared to traditional agriculture.

Solution: However, operating costs are very low. Thanks to water, fertilizer, and chemical savings and high yield, the investment returns within 2-3 years. Also, it can be started with small-scale pilot projects and expanded gradually.

Technical Knowledge Requirement

Challenge: Hydroponic systems require technical knowledge such as pH-EC control and nutrient formulation.

Esular Solution:

- User-friendly mobile application and web interface

- Automatic alarm and notification systems

- Remote technical support service

- Training materials and installation support in Turkish

Which Products are Grown in Vertical Farming and Hydroponic Systems?

Vertical farming and hydroponic systems give excellent results especially in some product groups. Here are the most popular and profitable products:

Leafy Greens

Lettuce Varieties: Curly lettuce, iceberg, romaine lettuce – It is the most popular hydroponic product. Harvested in 30-35 days.

Arugula and Cress: Grows fast, sold at high prices. 20-25 days harvest time.

Spinach: Baby spinach is especially in demand. High protein ratio.

Basil, Mint, Thyme: Aromatic plants are in high demand by restaurants and markets.

Fruity Vegetables

Cherry Tomato: Gives very high yield in hydroponic system. Sweet and flavored products are obtained.

Cucumber: Grown with a support system in vertical systems.

Pepper and Eggplant: Especially ornamental peppers and mini eggplants are popular.

Strawberry

Vertical strawberry systems have been attracting great interest in recent years. Production is carried out throughout the year and there is a high-price sales advantage. Esular substrate moisture sensors play a critical role in strawberry cultivation.

Establish Your Hydroponic and Vertical Farming Systems with Esular

Esular offers complete automation solutions for vertical farming and hydroponic systems. We are by your side with domestic production, technical support, and the advantage of affordable prices.

Advantages of Esular Solutions

Wireless Structure: All sensors and control units work wirelessly. Does not require complex wiring, installation is fast and easy. LoRa technology is used to provide a range of up to 5 kilometers.

Solar and Battery Powered: Does not require electricity infrastructure. Works uninterrupted for years with solar panels and long-lasting batteries.

Mobile and Web Access: Monitor and control facilities from anywhere in the world. iOS and Android applications are available.

Automatic Control: Sensor data automatically controls irrigation, ventilation, and heating systems. No manual intervention is needed.

Data Analysis and Reporting: Analyze historical data, perform yield optimization. Track your production performance with graphs and reports.

Modular and Expandable: You can start with a small system and easily expand according to need.

Other Esular Products

Other Esular solutions that complement your hydroponic and vertical farming systems:

Wireless Valve Control Systems: For automatic irrigation and nutrient solution control.

Irrigation Pool Control Systems: Water tank and pool management for large facilities.

Ventilation, heating, cooling automation.

Rain and Climate Stations: Provide system optimization by monitoring outdoor weather conditions.

The Future of Vertical Farming and Hydroponic Systems in Turkey

Turkey has great potential in agriculture with its geographical location and climate diversity. However, water scarcity, decreasing agricultural lands, and the effects of climate change make innovative solutions mandatory.

Current Status: Interest in vertical farming and hydroponic systems in Turkey has been increasing rapidly in recent years. Small-scale facilities have begun to be established in large cities such as Istanbul, Ankara, and Izmir. Some supermarket chains use mini vertical farming units in their greengrocer sections.

Government Supports: The Ministry of Agriculture and Forestry supports smart agriculture and soilless agriculture projects. Grants and loan opportunities are available for greenhouse investments and technological equipment purchases.

Education and Research: Universities and agricultural research institutes conduct R&D studies on vertical farming and hydroponic systems. A vertical greenhouse research center was established at Yıldız Technical University.

Market Potential: 75 percent of Turkey's population lives in cities. Demand for fresh, local, pesticide-free products is increasing day by day. Vertical farming offers the ideal solution to meet this demand.

Export Opportunity: Turkey's proximity to Middle Eastern and European markets provides an advantage for the export of hydroponic products. There is great demand especially in the Gulf countries.

Conclusion: The Agriculture of the Future Begins Today

Vertical farming and hydroponic systems will play a critical role in meeting the food needs of the world population. It offers a strong alternative to traditional agriculture with its advantages such as water saving, high yield, pesticide-free production, and year-round harvest.

The key to success is the right equipment and automation. With Esular's wireless sensor and control systems in your vertical farming and hydroponic facilities:

- Control pH and EC values precisely

- Increase yield by optimizing CO2 levels

- Keep temperature and humidity parameters at ideal levels

- Monitor substrate moisture and nutrient concentration

- Monitor and manage the entire system remotely

- Provide water and energy savings

- Reduce labor costs

Take action today for future food security. Practice smart, sustainable, and profitable agriculture with Esular!

Price Warning: The prices mentioned in this article are the list prices at the date the content was published. For current prices and campaigns, please visit the product pages. Prices may vary.

Would You Like to Receive Information About Vertical Farming and Hydroponic System Solutions?

The Esular expert team will help you determine the most suitable sensor and automation solutions for your hydroponic and vertical farming project.

📞 Telephone: 0312 222 44 55

📧 E-mail: info@esular.comReview Products

Last Update: October 2025 | Reading Time: 12 minutes

Related Content:

- 📖

- 📖

- 📖

- 📖