The Importance of Solenoid Valves in Agricultural Irrigation Systems and Encountered Problems

In modern agricultural practices, water management plays a critical role in terms of efficiency and sustainability. In this context, solenoid valves, which are one of the basic components of automatic irrigation systems, are key elements that ensure water reaches the right place, at the right time, and in the right amount. However, as with every mechanical and electronic system, solenoid valves can occasionally show failures. These failures can lead to disruptions in irrigation schedules, water waste, deterioration of plant health, and serious economic losses.

Valve failures and control panel problems encountered in irrigation systems are not rare, especially in garden and agricultural areas using smart irrigation systems. Farmers and agricultural professionals frequently encounter questions such as 'I cannot stop my irrigation system', 'One of the irrigation heads is constantly rotating', or 'Why is my automatic irrigation not working?'. Such situations are usually caused by mechanical or electrical problems of the solenoid valves.

In this comprehensive guide, starting from the working principles of agricultural-type solenoid valves, we will examine common failure types (including issues specific to plastic and cast-type valves) in detail, the causes of these failures, and step-by-step solution methods. Additionally, we will highlight how Esular's innovative smart irrigation technologies minimize such failures and increase the efficiency of your irrigation systems. Our goal is to help our farmers and agricultural professionals manage their irrigation systems more effectively and offer practical and permanent solutions to the valve failures encountered. Smart irrigation systems play an important role in preventing such problems.

Basic Working Principle and Structure of Solenoid Valves

Solenoid valves used in agricultural irrigation systems are electromechanical devices that control water flow with electrical signals. The basic working principle of these valves is based on an electromagnetic field created through a coil moving a plunger or diaphragm to open and close the valve.

How Does a Solenoid Valve Work?

- Coil (Solenoid): It is a cylinder with wire wrapped around it, located at the top of the valve body. When the electrical signal from the control unit (timer) is applied to this coil, a magnetic field is formed.

- Plunger: It is a metal part that moves inside the coil. When the magnetic field is formed, the plunger is pulled up.

- Diaphragm (Membrane): It is a flexible barrier located inside the main body of the valve that controls the flow of water. The movement of the plunger changes the water pressure on the diaphragm, allowing the valve to open and close. The diaphragm is supported by a spring that ensures the valve remains in the closed position.

- Pilot Hole: It is a small hole that balances the pressure on the diaphragm. When the solenoid opens, water is discharged from the top of the diaphragm through this hole, and the pressure difference under the diaphragm opens the valve.

When the electrical signal reaches the coil, the magnetic field pulls the plunger up. This movement opens a small pilot hole on the diaphragm. When the water pressure on top of the diaphragm is discharged through this hole, the pressure under the diaphragm becomes higher than the pressure on top, and the diaphragm lifts up, opening the valve. Water flow begins. When the electrical signal is cut, the magnetic field disappears, the plunger goes down and closes the pilot hole. The pressure on top of the diaphragm increases again, and with the help of the spring, the diaphragm goes down and closes the valve, stopping the water flow.

Solenoid Valve Types and Features

Solenoid valves used in agricultural irrigation systems are generally classified according to the materials they are made of and their working principles. Each type has its own unique advantages, disadvantages, and areas of use.

Plastic Composite Solenoid Valves

Plastic composite solenoid valves are widely preferred in small and medium-scale agricultural areas, gardens, and landscape irrigation systems due to their lightness, resistance to corrosion, and generally more affordable prices. These valves are usually produced from high-quality engineering plastics (for example, nylon or PVC).

Advantages:

- Corrosion Resistance: They are more resistant to rusting and chemical wear compared to metal valves, making them ideal for use in fertilization systems.

- Lightness: They are easy to transport and install.

- Cost Effectiveness: They are generally more economical than cast-type valves.

- Easy Maintenance: Assembly and disassembly processes are usually simpler.

Disadvantages:

- Pressure and Temperature Limits: They may not be as resistant to high pressure and extreme temperature conditions as metal valves.

- Mechanical Durability: They can be more sensitive to physical impacts and wear.

- UV Resistance: They may experience material fatigue if exposed to direct sunlight for a long time (this problem is minimized in high-quality products).

Areas of Use: Home gardens, parks, small agricultural plots, greenhouse irrigation systems, drip irrigation lines.

Cast Type Solenoid Valves (Brass, Iron, Stainless Steel)

Cast type solenoid valves are generally produced from metals such as brass, iron, or stainless steel. These valves are preferred in large-scale agricultural lands and industrial irrigation projects where there is high pressure, high flow rates, and harsh environmental conditions.

Advantages:

- High Durability: They are extremely resistant to mechanical impacts, wear, and high pressure.

- Wide Temperature Range: They can be used safely in a wide range of temperatures.

- High Flow Capacity: Since they are generally produced in larger diameters, they allow for high water flow speeds and rates.

- Long Life: When maintained correctly, they can work problem-free for many years.

Disadvantages:

- Corrosion Risk: Especially iron valves may carry a risk of rusting depending on water quality. Brass and stainless steel are better in this regard, but their costs are high.

- Weight and Installation Difficulty: Due to their weight, they are more difficult to transport and install.

- Cost: They are more expensive than plastic valves.

Areas of Use: Large agricultural lands (pivot irrigation, center pivot), main distribution lines, industrial irrigation systems, high-pressure applications.

Normally Open (NO) and Normally Closed (NC) Valves

- Normally Closed (NC) Solenoid Valves: These are valves that are closed when no electrical signal is received and open when electricity is provided. It is the most commonly used type in agricultural irrigation systems because it prevents water waste by automatically cutting the water flow in case of a power outage.

- Normally Open (NO) Solenoid Valves: These are valves that are open when no electrical signal is received and close when electricity is provided. Although less common, they are used in applications where continuous water flow is desired but must be cut in certain situations.

Latching (Locking) Solenoid Valves and Standard AC Valves

Energy efficiency and remote control are of great importance in agricultural irrigation systems, especially in solar-powered or battery-operated systems. In this context, there are significant differences between latching (locking) solenoid valves and standard AC (alternating current) solenoid valves.

Standard AC (Alternating Current) Solenoid Valves:

- Working Principle: These valves open when alternating current (usually 24V AC) is continuously applied to the coil and close when the current is cut. They need continuous energy to stay open.

- Advantages: They have simple structures, widespread availability, and generally lower initial costs. Ideal in areas where there is a reliable grid electricity source.

- Disadvantages: Energy efficiency is low due to continuous energy consumption. Valves close during power outages (for NC type), which can be undesirable in some cases. Voltage drops may occur over long cable distances.

- Areas of Use: Garden irrigation systems connected to the city grid, industrial facilities, areas with short cable distances.

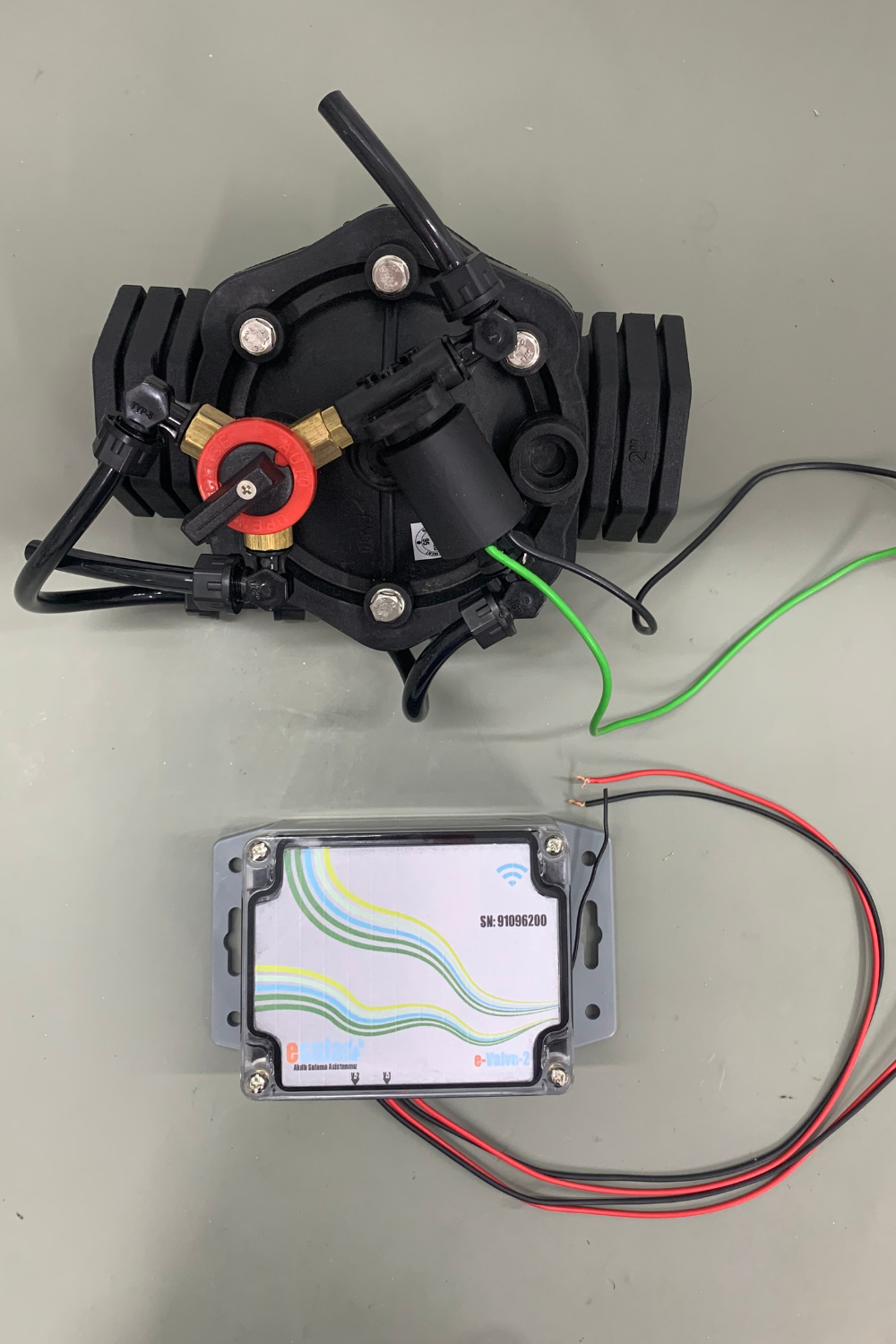

Latching (Locking) DC (Direct Current) Solenoid Valves:

- Working Principle: These valves open with a short-term electrical pulse and close with another short pulse. They do not need continuous energy to maintain their open or closed positions, which makes them extremely energy efficient.

- Advantages: Thanks to very low energy consumption, they are perfect for battery or solar-powered systems. They are less affected by voltage drops over long cable distances. They maintain their last position during power outages. Esular's LoRa battery-powered 9V solenoid control units use this technology effectively.

- Disadvantages: Their initial costs may be slightly higher than standard AC valves. The control system must manage pulse signals correctly.

- Areas of Use: Remote agricultural lands, solar-powered irrigation systems, battery-operated control units, IoT-based agricultural solutions requiring wireless valve control.

Common Solenoid Valve Failures and Diagnostic Methods

Since solenoid valves are the heart of irrigation systems, any failure occurring in these valves can negatively affect the operation of the entire system. Understanding the problems frequently encountered by farmers and the basic causes of these problems is critical for making fast and accurate diagnoses. Below are the most common solenoid valve failures encountered in agricultural irrigation systems and their possible causes:

Irrigation Systems Solenoid Valve and Failures: Frequently Asked Questions from Farmers

- Question 1: I cannot stop my irrigation system? This situation is usually caused by a mechanical blockage causing the valve to stay open or a continuous electrical signal coming from the control unit.

- Question 2: Why is the irrigation control unit (Timer) clock falling behind? The internal battery of the control unit running out or irregularities in the power supply can lead to this problem.

- Question 4: One of the irrigation heads is constantly rotating? This indicates that the relevant solenoid valve is not closing or is staying partially open. Debris inside or diaphragm damage are common causes.

- Question 5: There is a water leak in my garden but I cannot find it? Leaks occurring in underground pipelines or valve connections usually cause water loss that is not visible to the eye. Cracks in the solenoid valve's seals or body can also lead to leakage.

- Question 6: Why is my automatic irrigation not working? It could have many causes such as electrical connection problems, coil failure, control unit error, or mechanical locking of the valve.

- Question 7: When I plug my control panel (Rain Bird or Hunter etc.) in, the screen does not appear? It indicates a problem with the control panel's power supply, internal fuse, or power board.

- Question 8: How do I Reset my control panel? The reset procedure for each brand is different; it is usually done by cutting the power, waiting for a certain period, and then reconnecting, or through a special button combination.

- Question 9: How can I adjust the irrigation heads? The throw distance and direction of the irrigation heads are usually adjusted via adjustment screws or rotating mechanisms on the head.

- Question 10: How do I reduce the throw distance or flow rate of the irrigation heads? It can be adjusted by flow control valves on the head or by changing the nozzles.

- Question 11: How do I set the irrigation system control panel? Irrigation programs, start times, irrigation durations, and days are set according to the control panel's user manual.

You encounter many such questions. In case of failures and technical issues, KANSU irrigation systems has always been there for our customers. Kansu irrigation, providing telephone support, shares its 18 years of experience with you. Our company, involved in large projects, works with a focus on failures in the work performed and affordable prices and customer satisfaction for gardens without irrigation systems.

Valve Does Not Open or Close: Electrical and Mechanical Problems

A solenoid valve not opening or closing is one of the most critical failures that leads to the complete disruption of irrigation schedules. Such problems usually arise from electrical or mechanical causes.

Electrical Failures (Coil Problems)

The coil, which is the electrically operated part of the solenoid valve, activates the valve by creating a magnetic field. Coil failures cause the valve not to respond to electrical signals.

- Open Circuit (Broken Cable): The electrical current is cut as a result of the cables going to the coil breaking or the connection points loosening. You can check if there is an open circuit by measuring resistance from the coil connection points with a multimeter. A healthy coil should show a certain resistance value (for example, between 20-60 Ohms).

- Short Circuit: In the event that the coil windings short circuit internally or the cables touch each other, excessive current is drawn and the coil does not work. This situation can also damage the control unit. Reading low or zero resistance with a multimeter may indicate a short circuit.

- Wrong Voltage: Applying an unsuitable voltage to the valve (for example, DC voltage instead of 24V AC or vice versa) causes the coil not to work or to be damaged. It is important to check the output voltage of the control unit.

- Control Unit Failure: A control unit that cannot send the correct electrical signal to the valve can also cause the valve not to work. You can test the functionality of the control unit by connecting another valve to the same output.

Mechanical Failures (Diaphragm, Plunger, Spring Problems)

When electrical problems are excluded, problems in the internal mechanisms of the valve lead to valve failures.

- Blockage (Debris): Sand, mud, algae, or other particles in the water can get stuck between the valve's diaphragm or plunger, preventing the valve from fully closing or opening. This is frequently seen especially in agricultural irrigation systems using dirty water sources.

- Torn or Deformed Diaphragm: The diaphragm is the flexible barrier that controls water flow. It can tear, be punctured, or deform over time or due to high pressure. A torn diaphragm leads to the valve leaking water or not closing at all.

- Deformed or Broken Spring: The spring that keeps the diaphragm in the closed position can weaken or break over time. In this case, the diaphragm cannot close with sufficient pressure and the valve may stay constantly open.

- Stuck Plunger: The metal plunger inside the coil can get stuck due to rusting, calcification, or mechanical damage and cannot move when the coil is energized. This also causes the valve not to open.

Continuous Water Flow (Valve Does Not Close) and Water Leaks

A solenoid valve not closing or constantly leaking water is a significant problem that can cause both water waste and damage to plant health. This situation is usually caused by the following reasons:

WHY DOES THE VALVE LEAK WATER WHEN CLOSED?

- There may be debris in the valve; this causes the valve to stay open. To fix this, you will need to disassemble the valve, rinse all parts with clean water, and reinstall the valve. If you cannot place the valve box lids or fix the valve, it is recommended to contact the supplier who installed your system or use our Professional Supplier Application page to help you find a professional supplier near you.

WHY DOES MY SPRINKLER SYSTEM CONTINUE TO WORK EVEN THOUGH THE CONTROLLER IS UNPLUGGED?

- It is likely that the valves were opened manually. You will need to place your valve box lids and turn the solenoids on the valve until they sit comfortably. The solenoid is located on the top of the valve and resembles a cylinder with two wires coming out of it.

- There may be debris in the valve; this causes the valve to stay open. To fix this, you will need to disassemble the valve, rinse all parts with clean water, and reinstall the valve. If you cannot place the valve box lids or fix the valve, it is recommended to contact the supplier who installed your system or visit our Professional Supplier Application page to help you find a supplier near you.

In addition to the situations above, other factors that may cause the valve not to close or to leak are:

- Diaphragm Damage: Tearing, puncturing, or hardening of the diaphragm leads to water leaking or the valve not closing fully.

- Low Pressure Difference: Some solenoid valves need a certain minimum pressure difference to work correctly. If the pressure in the system is too low, the valve may not close fully.

- Valve Body Damage: Cracks occurring in the valve body due to freezing, physical impact, or excessive pressure can also cause water leaks.

- Incorrect Assembly: Not placing the seals correctly during valve assembly or not tightening the connections sufficiently can also lead to leaks.

Low Water Flow or Pressure Problems

A general pressure drop in the irrigation system or low water flow in a specific area can lead to insufficient plant irrigation and yield loss. The causes of such problems related to the solenoid valve are:

- Partial Blockage: Debris or lime accumulating inside the valve can reduce flow by partially blocking the water passage. This situation can give the impression that the valve is not fully opening.

- Valve Sizing Error: Using a valve with too small a diameter that is not suitable for the system's flow and pressure requirements naturally leads to low flow.

- Pressure Regulator Problems: If there is a pressure regulator before the valve in the system, a failure or wrong adjustment in this regulator can affect the pressure reaching the valve and reduce flow.

- Partially Open Manual Control: Leaving the manual opening/closing lever of the solenoid valve or the solenoid itself partially open can reduce system pressure and affect flow in other areas.

Step-by-Step Solution Guide for Solenoid Valve Failures

Following a systematic approach to deal with solenoid valve failures ensures you solve the problem quickly and effectively. Here is a step-by-step solution guide for common failures:

1. Manual Control of the Solenoid Valve

In some cases, the valve may have been opened manually, not by the control unit, or a manual test may be needed to understand if the failure is electrical or mechanical.

- How do I manually open a zone control valve without using the controller? Turn the solenoid on the valve (the black cylinder with 2 wires coming out of it) slightly clockwise between 1/4 – 1/2 at a time. To close the valve, turn the solenoid counter-clockwise until it sits on the valve.

2. Cleaning Debris and Blockages in the Solenoid Valve

If the valve does not close or constantly leaks water, one of the most common causes is debris or dirt accumulated inside. The cleaning process must be done carefully and in accordance with the steps.

HOW DO I CLEAN DEBRIS IN THE IRRIGATION VALVE?

- Turn the controller to "System Off"; so it does not try to switch to a program.

- Turn off the main water source. Opening a valve under pressure is dangerous and can cause injury.

- Unscrew the solenoid (two-wire cylinder) and ensure the plunger is clean and moves freely. You can test the solenoid by manually operating this station from the controller and seeing if the plunger retracts when energized.

- Unscrew the cover screws or the jar-top according to your valve model. Be careful not to lose the diaphragm or the spring while pulling the cover from the body.

- The diaphragm may be placed in the body or fixed in the cover. Remove the diaphragm and the spring. Keep the direction of the diaphragm in mind so you can reinstall it the way it came out.

- Examine the diaphragm and the spring. The diaphragm should be clean, not wrinkled, not torn, and not punctured. The seal should be clean and not worn, and there should be no dents or scratches on it. To clean any accumulated debris, wash the diaphragm with clean water.

- The diaphragm spring should be intact and should spring back when pressed.

- Examine the valve body and clean debris, pebbles, or dirty water.

- The seal seat must be clean and not worn, with no gaps or notches on it.

- Examine the holes in the valve body and valve cover. All holes must be clean and able to pass water through them easily. A small piece of flexible wire can be passed through the holes to clear the blockage.

- Reinstall the valve in the reverse order it was removed. The diaphragm should sit on the lip in the seat where it matches in the body and cover. Screws or the jar-top should be tightened by hand. Excessive tightening can damage the valve.

3. Checking Electrical Connections and the Coil

If the valve still does not work after being mechanically cleaned, the problem may be electrical. These steps will help you check the electrical connections and the coil.

- Check Cable Connections: Ensure the cables coming to the valve are correctly connected to the control unit and that the connections are not loose or corroded.

- Voltage Control: Measure the voltage coming from the control unit to the valve coil with a multimeter. When a valve opening signal is sent, you should see the correct voltage (for example, 24V AC or 9V DC pulse) at the coil input.

- Coil Resistance Test: Disconnect the coil's cables from the valve and measure the coil's resistance with a multimeter. You should get a reading within the value range specified by the manufacturer (usually between 20-60 Ohms). An open circuit (very high resistance) or short circuit (very low resistance) indicates a coil failure. A faulty coil must be replaced.

- Control Unit Test: If possible, test another working valve connected to the same zone or connect the suspicious valve to another output of the control unit to determine if there is a problem with the control unit itself.

4. Diaphragm and Spring Replacement

If there is a tear, hole, or excessive deformation in the diaphragm, or if the spring is weakened or broken, these parts will need to be replaced. These parts can usually be obtained from the valve manufacturer.

- Obtaining New Parts: Obtain original replacement diaphragms and springs suitable for your valve model.

- Replacement Steps: Open the valve by applying steps 1-5 of the cleaning steps above and remove the old diaphragm and spring. Ensure you place the new diaphragm in the correct direction and position the spring correctly. Reassemble the valve carefully.

The Role of Smart Irrigation Systems in Preventing Solenoid Valve Failures (Esular Perspective)

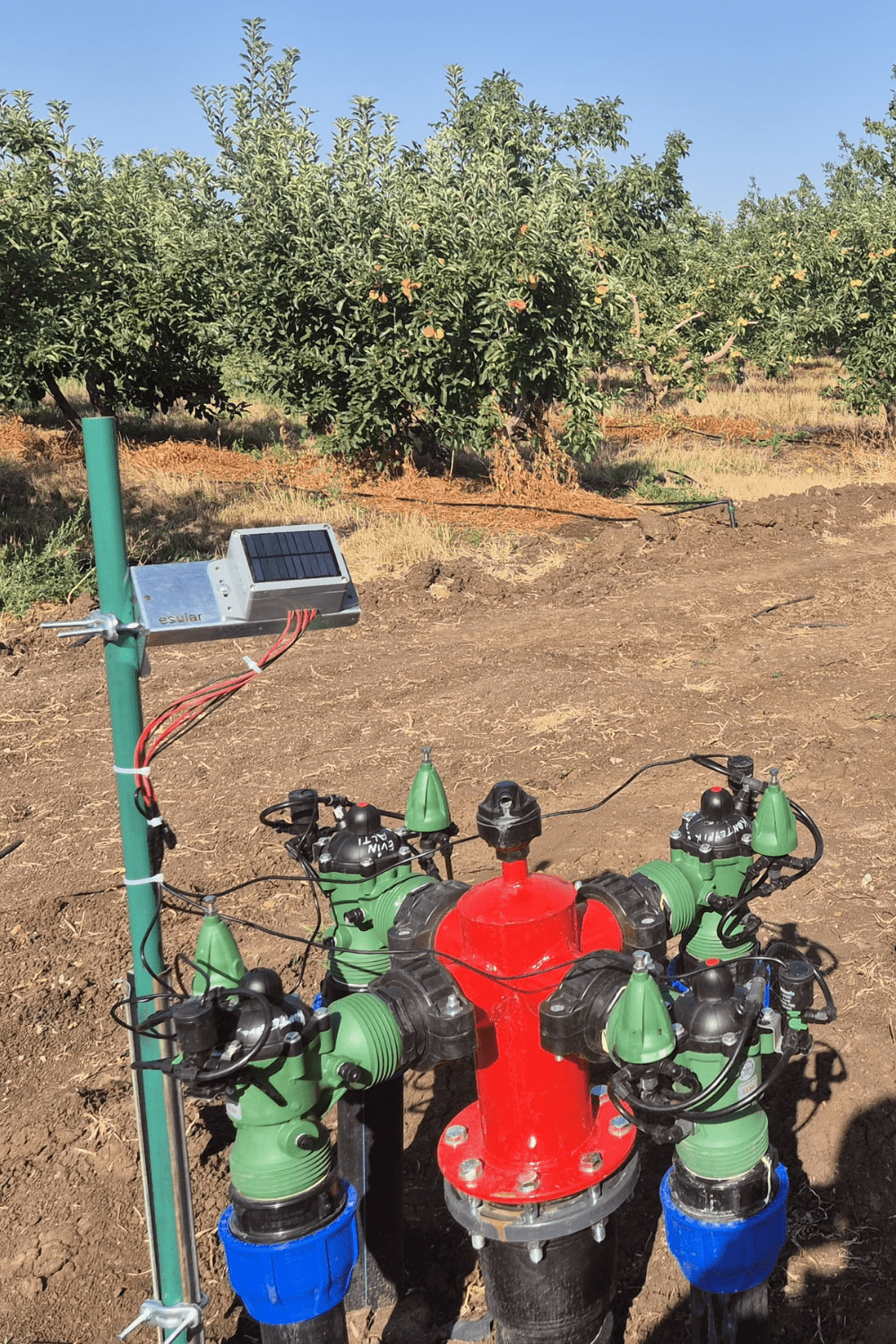

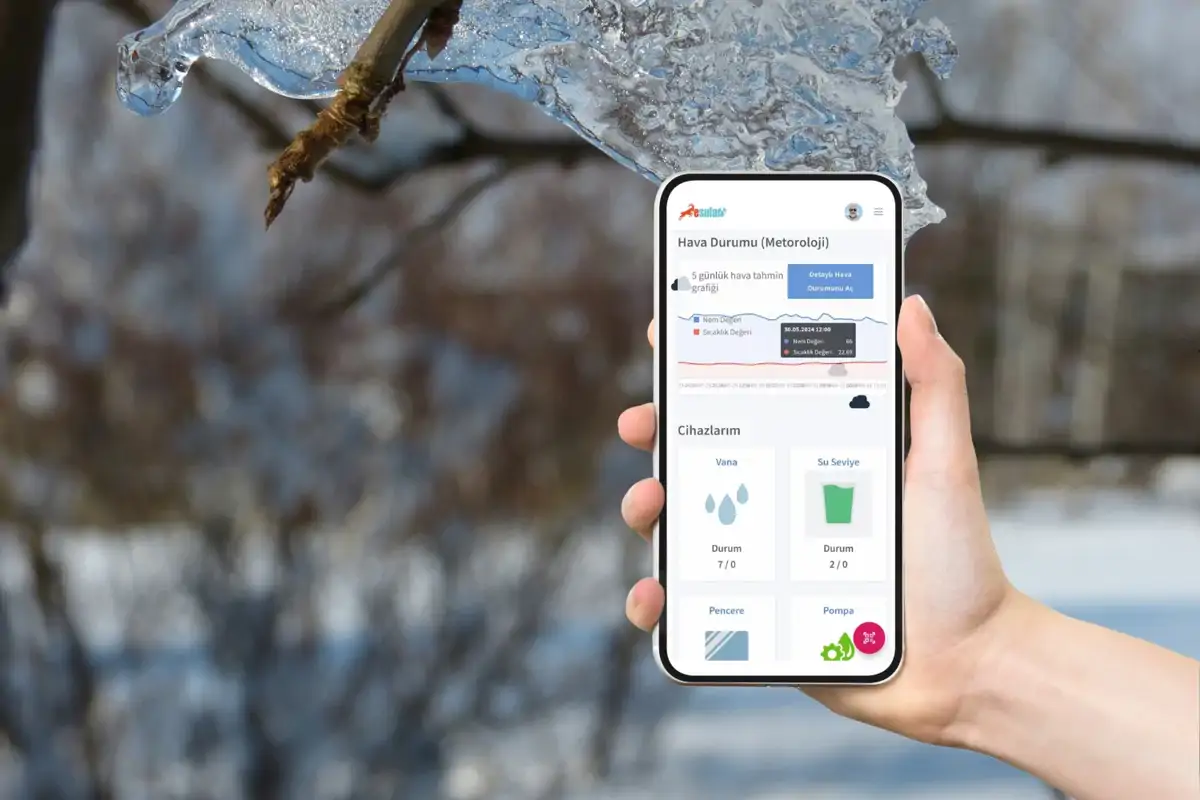

As Esular, we are aware of the problems caused by solenoid valve failures in agricultural irrigation systems. For this reason, the smart irrigation technologies we develop aim to minimize such failures and make your systems much more efficient, reliable, and easy to manage. Our smart systems offer significant advantages to farmers by eliminating the weak points of traditional irrigation methods.

Precise Control with Soil Moisture Sensors

Esular's soil moisture sensors constantly monitor the instantaneous moisture level of the soil. In this way, irrigation is performed according to the real water need of the plant and unnecessary irrigation is prevented. The reduction of unnecessary valve opening/closing cycles significantly lowers the mechanical wear and failure risk of solenoid valves. Additionally, problems such as soil erosion and nutrient loss caused by excessive irrigation are also prevented. These sensors optimize irrigation decisions, extending valve life and reducing energy consumption. Research conducted worldwide shows that soil moisture sensors increase water use efficiency by 20% to 50%. (Source: FAO - Water Scarcity)

Remote Management with Wireless Valve Control Units

Esular's wireless valve control units offer the opportunity to manage solenoid valves remotely via a mobile application or web platform. In this way, farmers can check the status of the valves without going to the field, change irrigation programs instantly, and quickly intervene in potential failures. Thanks to wireless communication (such as LoRa technology), reliable control is provided even over long distances and wiring costs are eliminated. These systems minimize valve failures caused by human error (for example, forgetting to leave the valve open).

Early Warning System with Pressure and Flow Sensors

Esular's smart irrigation systems constantly monitor the flow rate and pressure of water thanks to pressure and flow sensors integrated into the main lines. Sudden pressure drops or abnormal flow values in the system can be an early indicator of a potential failure such as a pipe burst, valve blockage, or leak. Thanks to these sensors, the system automatically sends a warning or stops irrigation, preventing large-scale water loss and system damage. This proactive approach also prevents sudden loads on solenoid valves, extending their life.

Remote Management and Automatic Failure Detection Platform

Esular's central management platform offers the opportunity to monitor and manage the entire irrigation system from a single screen. Data from sensors are analyzed instantly and potential valve failures or abnormalities are detected automatically. For example, if a valve receives an opening command but no data comes from the flow sensor, the system can determine that there is a problem with the relevant valve and send an instant notification to the user. In this way, failures can be detected and intervened in before they grow. The platform also offers the opportunity to track valve performance and create preventive maintenance plans by recording irrigation history.

Energy Efficient Latching Valve Solutions

Especially for solar-powered or battery-operated irrigation systems, Esular prefers energy-efficient latching (locking) solenoid valves and control units. Since these valves only need a short electrical pulse at the moment of opening and closing, they consume much less energy. This offers uninterrupted and reliable irrigation in remote lands or systems that need to work independently of the electricity grid. Esular's solar-paneled valve control units work integrated with these latching valves, ensuring maximum energy efficiency.

Points to Consider in Solenoid Valve Selection

Choosing the right solenoid valve is fundamental for your irrigation system to be long-lasting and problem-free. Incorrect valve selection can lead to frequent failures, inefficient irrigation, and unnecessary costs. Here are the critical factors you should consider when choosing a valve:

1. Material Type and Durability

The material the valve will be made of should be determined according to the conditions of use and water quality.

- Plastic Composite Valves: Generally more cost-effective and corrosion-resistant. Ideal for small and medium-scale applications, garden irrigation, and fertilization systems. However, they may not be as durable as metal valves under high pressure and temperature conditions.

- Cast Type Valves (Brass, Stainless Steel): Offer superior durability under high pressure, high flow, and harsh environmental conditions. Suitable for large agricultural lands, main distribution lines, and industrial applications. While brass is corrosion-resistant, stainless steel provides the highest resistance. For a detailed comparison, you can check our Agricultural Solenoid Valve Selection guide.

2. Pressure and Flow Requirements

The maximum operating pressure of the system and the water flow rate that must pass through the valve are the main factors in determining valve size and type. The pressure resistance of the valves should be such that it meets the peak pressure of the system. The flow capacity should be high enough to meet the water needs of the area to be irrigated. An incorrectly sized valve can cause pressure drops or insufficient irrigation.

3. Voltage Type (AC vs. DC Latching)

Selecting a valve suitable for the voltage type of your control unit and energy source is vital. While 24V AC valves are generally preferred for systems operating with grid electricity, energy-efficient 9V DC latching valves are more suitable for remote systems powered by batteries or solar energy. Our 12V DC Latching vs 24V AC Solenoid Valve article offers more information on this subject.

4. Water Quality and Filtration Need

The amount of particulate matter in the irrigation water directly affects valve selection. If dirty water sources (river, pond, well) are used, appropriate filtration systems (for example, Esular's drip irrigation filter cleaning and smart tracking system) must be used to prevent valve blockages, and valve models more resistant to debris should be preferred accordingly. Regular maintenance of filters greatly reduces valve failures.

5. Certifications and Standards

Ensure the selected solenoid valves comply with international and local agricultural standards. High-quality and certified products offer long-lasting and reliable performance.

Conclusion

Agricultural solenoid valves are indispensable for modern irrigation systems and provide great efficiency when they work correctly. However, it is inevitable that they encounter electrical or mechanical failures. In this comprehensive guide, we have examined the basic causes of valve failures, diagnostic methods, and step-by-step solution ways in detail. It should not be forgotten that regular maintenance and correct valve selection are the most effective ways to prevent such problems.

As Esular, we aim to minimize solenoid valve failures and make your irrigation systems more efficient with the smart irrigation technologies we have developed. Thanks to our innovative solutions such as soil moisture sensors, wireless valve control units, pressure and flow sensors, you can optimize your irrigation decisions, detect potential problems early, and produce instant solutions with remote intervention. Our smart systems protect both the environment by preventing water waste and reduce the operating costs of our farmers.

To increase efficiency in your irrigation systems and prevent potential valve failures, discover Esular's smart solutions! To get more information or to contact our experts for a custom irrigation project, visit our Esular website immediately.

Sıkça Sorulan Sorular

Why does the solenoid valve in agricultural irrigation systems not close or constantly leak water?

Solenoid valves not closing or leaking water is usually caused by particles such as debris, sand, or mud accumulating inside and clogging the diaphragm. Additionally, tearing, puncturing, or deformation of the diaphragm, weakening of the spring, or cracks in the valve body can lead to such failures. Low system pressure or incorrect assembly can also prevent the valve from fully closing, which causes water waste and damages plant health.

How are solenoid valve failures diagnosed and what are the step-by-step solutions?

To diagnose solenoid valve failures, first a manual control of the valve should be performed, then electrical connections and coil resistance should be tested with a multimeter. For mechanical problems, the valve should be disassembled and the debris inside cleaned, the diaphragm and spring should be checked and replaced if necessary. The accuracy of the voltage coming from the control unit should also be checked to determine if there is an electrical problem.

What are the main differences between plastic composite and cast-type solenoid valves and in which case should which be preferred?

Plastic composite solenoid valves are lightweight, corrosion-resistant, and cost-effective, making them ideal for small-scale garden and greenhouse irrigation. Cast-type (brass, stainless steel) valves offer superior durability under high pressure, high flow, and harsh conditions, making them more suitable for large agricultural lands and industrial systems. The choice should be made according to the pressure, flow, and water quality requirements of the system.

What role do smart irrigation systems play in preventing solenoid valve failures?

Smart irrigation systems optimize irrigation decisions through soil moisture, pressure, and flow sensors, reducing unnecessary valve opening/closing cycles and lowering mechanical wear. While wireless valve control units offer remote management opportunities, automatic failure detection platforms identify potential problems early, preventing major damage. In this way, valve life is extended, water waste is prevented, and system efficiency is increased.

What are the main advantages of latching (locking) solenoid valves compared to standard AC valves?

Latching (locking) solenoid valves only need a short electrical pulse for opening and closing and do not consume continuous energy to maintain their open or closed positions. Thanks to these features, they are extremely energy-efficient for battery or solar-powered systems. Additionally, they are less affected by voltage drops over long cable distances and offer more reliable operation by maintaining their last position during power outages.

How are debris and blockages in the irrigation valve cleaned step by step?

To clean debris in the irrigation valve, first the main water source must be turned off and the control unit must be set to the “System Off” position. Then the solenoid is unscrewed to check if the plunger moves freely. After opening the valve cover and removing the diaphragm and spring, all parts are washed with clean water to remove debris and the holes are checked to be open. Finally, the valve is carefully reassembled, avoiding excessive tightening.

Which critical factors should be considered when choosing a solenoid valve?

When choosing a solenoid valve, factors such as the type of material (plastic or cast), the maximum operating pressure and flow requirements of the system, the voltage type of the control unit (AC or DC latching), and the quality of the irrigation water (filtration need) are of critical importance. Additionally, the valve's compliance with international standards, its certifications, and the support provided by the manufacturer should be considered for a long-lasting and problem-free system.